- Power Transmission - Mechanical components

- Mechanical Transmission

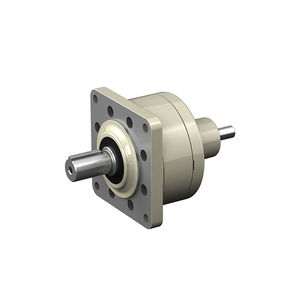

- Helical gear gear reducer

- SUMITOMO (SHI) Cyclo Drive Germany GmbH

Bevel gear reducer PARAMAX® 9000helical gearright angleparallel-shaft

Add to favorites

Compare this product

Characteristics

- Type

- bevel, helical gear

- Shaft orientation

- right angle, parallel-shaft

- Shaft configuration

- hollow-shaft, solid-shaft

- Torque

- > 10 kNm, 2 - 5 kNm, 5 - 10 kNm

- Configuration

- compact, flange

- Performance

- high-torque, high load capacity

- Applications

- industrial, for the sugar industry, shaft

- Other characteristics

- vertical, mounted

- Gear ratio

Min.: 6.3 unit

Max.: 500 unit

Description

Flexible gearbox series, engineered and produced in Europe

Overview

Local engineered and produced range available in 8 sizes, ensuring short delivery times and quick support. Other sizes available directly from the global factories.

Parallel and right Angle - 2/3/4 stage gearboxes with solid and hollow output shaft (key, shrink disk).

Specifically for small and medium torque applications with horizontal output shaft (material handling applications, cranes, horizontal mixers, …).

Complete Drive packages with baseplate/motor lantern available including couplings, brakes, and motors.

Numerous other options and accessories: condition monitoring, backstop, cooling fan, …

For larger gearboxes above 80kNm consider also using the Hansen P4 horizontal- and Hansen P4 vertical multistage series

Product Features

Engineering and application knowledge

Quick Technical Support and Service in Europe, Middle East, India and Africa

Local production & inventory stock

Short ways to customers to ensure short delivery time. Enables rush deliveries for exceptional circumstances

Fine torque grading

Best possible selection for low- to medium torques. Together with Hansen P4 a large portfolio is offered.

Powerful Gear Geometry

For maximum load capacity, minimum losses & lower noise levels

Various application usage

Flexible mounting possibilities, typically for material handling, conveyors, cranes.

Numerous Instruments & Accessories

Condition monitoring instruments, Cooling devices & Complete Drive Packages (including base plates or lantern housings, motors, couplings, ...)

ATEX / UKCA EX certification

Certification for explosive environments

Catalogs

Other SUMITOMO (SHI) Cyclo Drive Germany GmbH products

Reducers

Related Searches

- Planetary gearbox

- Coaxial gearbox

- Right angle gearbox

- Precision gearbox

- Gear train gearbox

- Compact gearbox

- Solid-shaft gearbox

- Hollow-shaft gearbox

- Industrial gear reducer

- Transmission gearbox

- Shaft gearbox

- Helical gear gearbox

- Multi-stage gearbox

- Single-stage gearbox

- Two-stage gearbox

- Machine gearbox

- Bevel gearbox

- High-performance gearbox

- Electric motor gearbox

- Modular gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.