- Environment - Health - Safety

- Water Treatment

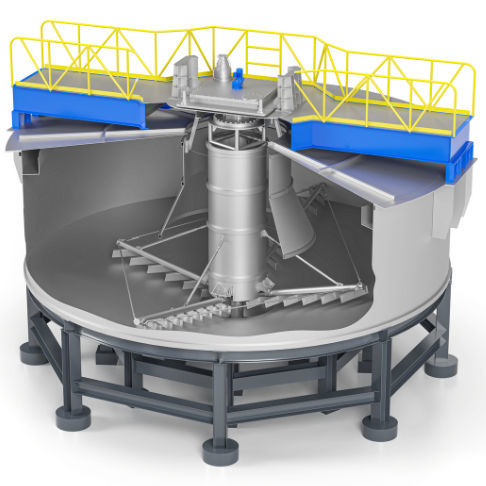

- Central drive thickener

- SUNKAIER INDUSTRIAL TECHNOLOGY CO.,LTD.

Central drive thickener for wastewater treatment plants

Add to favorites

Compare this product

Characteristics

- Options

- central drive

- Applications

- for wastewater treatment plants

Description

Clarifier is designed to remove suspended solids from a liquid to produce clear water or another liquid. This process is commonly used in wastewater treatment plants, industrial water treatment systems, and other applications where clean liquid is required.

Thickener, on the other hand, is used to concentrate suspended solids by removing free water. It's often employed in mineral processing, waste management, and other industries where it's necessary to reduce the volume of slurry for further handling or disposal.

A high-rate thickener is a type of solid-liquid separation equipment used in various industries, including mining, mineral processing, and wastewater treatment. It is designed to efficiently separate solids from liquids by settling the solids to the bottom of the vessel while allowing the clarified liquid (overflow) to be removed from the top.

Here are some key features and components of a high-rate thickener:

1. Design: High-rate thickeners are typically large tanks or vessels with a central shaft and rake arms that slowly rotate to collect settled solids at the bottom and move them towards the center where they can be discharged as underflow (concentrated slurry).

2. Settling Zone: The main body of the thickener provides a large surface area for particles to settle out of suspension. This zone is crucial for achieving efficient separation.

3. Rake Mechanism: Rakes or scrapers move across the bottom of the tank to consolidate the settled solids and push them towards the center. These rakes are typically driven by a central mechanism and operate at very low speeds to minimize resuspension of settled solids.

Catalogs

No catalogs are available for this product.

See all of SUNKAIER INDUSTRIAL TECHNOLOGY CO.,LTD.‘s catalogsOther SUNKAIER INDUSTRIAL TECHNOLOGY CO.,LTD. products

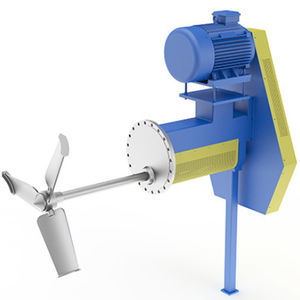

Mixing equipment

Related Searches

- Dynamic homogenizer

- Batch homogenizer

- Liquid agitator

- Homogenizer for the food industry

- Agitator for the chemical industry

- Agitator for the pharmaceutical industry

- Paddle blender

- Water treatment agitator

- Thickener

- Rotary blender

- Gas/liquid agitator

- Bottom-entry agitator

- Side-mount agitator

- Blender for the recycling industry

- Agitator for the mining industry

- Central drive thickener

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.