- Industrial machines and equipment

- Surface Treatment Equipment

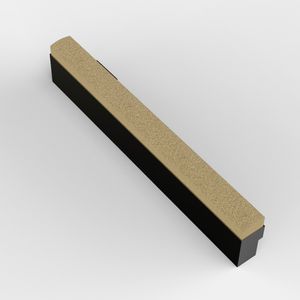

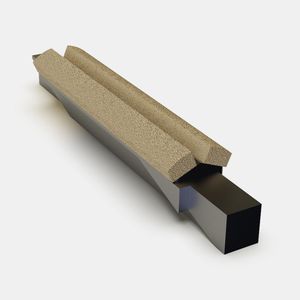

- Silicon carbide abrasive stone

- Sunnen Products Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Silicon carbide abrasive stone aluminum oxide

Add to favorites

Compare this product

Characteristics

- Options

- aluminum oxide, silicon carbide

Description

Abrasives improve the efficiency and quality of any honing operation. Ideal in both Sunnen equipment and other high-production machines, Sunnen designs abrasives to fit and function in any style honing tool, including those manufactured by Nagel, Gehring, Barnes, OTW, Kadia and others. Our abrasives provide increased tool life and cost-per-part reductions to your facility. Plus, we offer new replacement tooling for any application.

Trust in Sunnen’s 40+ Years of Research and Development

We’ve incorporated more than 40 years of research and development into a complete line of honing abrasives. In fact, we have the largest selection of honing abrasives in the world.

From conventional abrasives such as Aluminum Oxide AL OX and Silicon Carbide SiC through state-of-the-art Metal Bonded Superabrasives made using diamond and borazon (CBN), Sunnen can provide the right product for your machine in any style, size, or shape.

With Sunnen, You Can Expect Precision and Accuracy

With a legacy of nearly 100 years in supporting the world’s most demanding honing applications within the high-precision metalworking industry, Sunnen offers products you can trust. Abrasives are highly engineered and built to exacting customer requirements. With Sunnen products, you can expect:

A variety of abrasive materials, bond types, grit sizes, and stone configurations.Abrasives improve the efficiency and quality of any honing operation. Ideal in both Sunnen equipment and other high-production machines, Sunnen designs abrasives to fit and function in any style honing tool, including those manufactured by Nagel, Gehring, Barnes, OTW, Kadia and others.

Catalogs

No catalogs are available for this product.

See all of Sunnen Products Company‘s catalogsRelated Searches

- Surface treatment technical brush

- Metal wire brush

- Strip brush

- Finishing brush

- Abrasive brush

- SUNNEN abrasive stone

- Silicon carbide brush

- SUNNEN aluminum oxide abrasive stone

- SUNNEN silicon carbide abrasive stone

- SUNNEN honing tool

- Tool brush

- Honing brush

- Finishing hone

- Cylinder hone

- SUNNEN diamond honing tool

- Modular honing tool

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.