- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

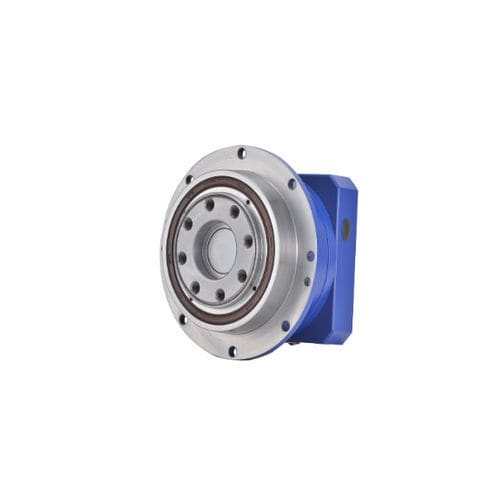

Planetary gear reducer DG seriescoaxialsolid-shaft200 - 500 Nm

Add to favorites

Compare this product

Characteristics

- Type

- planetary

- Shaft orientation

- coaxial

- Shaft configuration

- solid-shaft

- Torque

- 200 - 500 Nm, 100 - 200 Nm, 20 - 50 Nm, 50 - 100 Nm, 500 - 1000 Nm, > 10 kNm, 1 - 2 kNm, 10 - 20 Nm, 2 - 5 kNm

- Configuration

- compact, modular, flange

- Number of stages

- single-stage, two-stage

- Performance

- high-precision, high-performance, low-noise, low-backlash, high-efficiency, maintenance-free, high-capacity

- Applications

- for servo motors, for robots, machine, for machines, for automation, for lathes, shaft

- Other characteristics

- with plate

- Rotational speed

Min.: 0 rpm

(0 rad.min-1)Max.: 10,000 rpm

(62,831.85 rad.min-1)- Backlash

Min.: 0.02 °

Max.: 0.12 °

- Gear ratio

Min.: 4 unit

Max.: 100 unit

Description

Output shaft is designed with the flange design. Carrier and flange come in one-piece structure to ensure both the concentricity and bong strength of within the accessories. Compact design is perfect for the limited space.

High positioning accuracy

Precision grinding gear, smooth of gear surface, high accuracy of tooth profile.

Compact design

Shorter than general shaft type reducer, suited on the limited space.。

Easy Installation

For the modular input bushing and the changeable connecting plate according to the customer's brand of servo-motor.

Easy maintenance

The gear with the deep carburizing heat treatment and precision grinding process, making its high stiffness and mesh accurate, prolonging the service life and low noise.

Best-chosen German synthetic oil lubricant and protect the components inside the gearbox, oil-filled free

Select superior quality, heat-resistance, wear-resistance seal, get the better sealing performance.

Catalogs

DG series

7 Pages

Related Searches

- Planetary gearbox

- Coaxial gearbox

- Right angle gearbox

- Precision gearbox

- Gear train gearbox

- Compact gearbox

- Solid-shaft gearbox

- Hollow-shaft gearbox

- Industrial gear reducer

- Shaft gearbox

- Helical gear gearbox

- Multi-stage gearbox

- Single-stage gearbox

- Two-stage gearbox

- Machine gearbox

- Bevel gearbox

- High-performance gearbox

- Low-noise gearbox

- Electric motor gearbox

- Modular gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.