- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

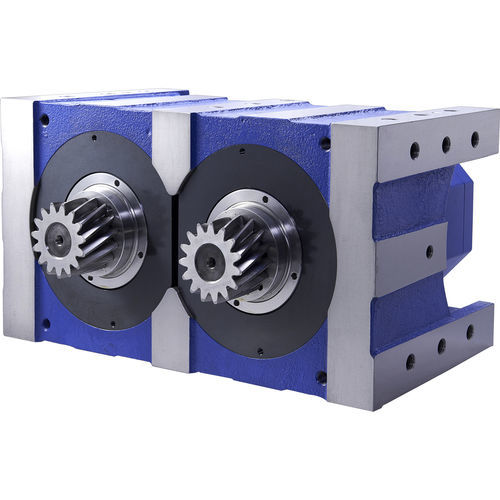

Rack-and-pinion drive gear reducer DMU seriesplanetarycoaxialpinion shaft

Add to favorites

Compare this product

Characteristics

- Type

- planetary

- Shaft orientation

- coaxial

- Shaft configuration

- pinion shaft, dual-shaft, multiple-output

- Torque

- 500 - 1000 Nm, > 10 kNm, 1 - 2 kNm, 2 - 5 kNm, 5 - 10 kNm

- Configuration

- compact, modular

- Number of stages

- single-stage, three-stage, two-stage

- Performance

- low-noise, high-precision, high-performance, high-efficiency, low-backlash, high-torque, maintenance-free, high-power, high-rigidity, high-capacity, for heavy loads, zero-backlash

- Applications

- for servo motors, for industrial applications, for heavy-duty applications, for machines, for rack-and-pinion drives, for lathes, industrial, for machine tools, for grinding machines

- Other characteristics

- high-quality, double

- Rotational speed

Min.: 2,000 rpm

(12,566.37 rad.min-1)Max.: 4,000 rpm

(25,132.74 rad.min-1)

Description

DMU (Box design) Mechanical Backlash-free

Specially designed machinery is able to eliminate clearance from gearbox inner and from between pinions and racks. Driven by a single servo motor, enclosed mechanical preload system is more efficient than electrical preload system.

Enclosed Gearbox

Specially designed machinery is able to eliminate clearance from the gearbox inner and from between pinions and racks. This completely supplements and clears up the backlash of manufacture or/and installation while gearboxes drive both pinions and racks.

Cost saving

Mechanical preload system, driven by a single servo motor, can reach the goal of electrical preload system, save controller and driver cost.

Backlash eliminating enables processing tool tracks stable, which prolongs tool life.

Easy to set up

Parameter setting can be easier for enclosed mechanical preload system, driven by a single servo motor, than electrical preload system.

Better processing surface smooth and accuracy

Backlash reducing enables improved processing surface smoothness and accuracy.

Huge Torsional Rigidity

For the well-designed structure and high duty material of taper roller bearing, the output shaft of the reducer can bear the huge axial and radial load, which could be wide application.

High Dynamics

One-piece output design, special high strength the fewer teeth of pinion and smaller servo motor, achieve the low moment of inertia.

Precise Positioning

Precision gear grinding tooth surface smooth, precise tooth.

For an excellent design, high accuracy and low moments of inertia.

.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Sunus Tech Co., Ltd.‘s catalogsRelated Searches

- Planetary gearbox

- Coaxial gearbox

- Right angle gearbox

- Precision gearbox

- Gear train gearbox

- Compact gearbox

- Solid-shaft gearbox

- Hollow-shaft gearbox

- Industrial gear reducer

- Shaft gearbox

- Helical gear gearbox

- Multi-stage gearbox

- Single-stage gearbox

- Two-stage gearbox

- Machine gearbox

- Bevel gearbox

- High-performance gearbox

- Low-noise gearbox

- Electric motor gearbox

- Modular gearbox

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.