Power cable strandedcopperaluminum

Add to favorites

Compare this product

Characteristics

- Type

- power

- Configuration

- stranded

- Core material

- copper, aluminum

- Applications

- distribution

- Number of wire

- single-core

- Material of the insulation

- XLPE-insulated, PVC-sheathed

- Norms

- IEC

- Other characteristics

- multi-core

- Nominal voltage

33 kV

- Temperature

20 °C, 30 °C

(68 °F, 86 °F)

Description

XLPE Insulated Power Cable at Rated Voltage 19/33kV

Executive Standard

This products will be manufactured as per BS 6622, BS EN/IEC 60228 standards.

Application Scopes

The cables are applied to power transmission and distribution system at rated voltage19/33kV

Operating Features

1.Rated Voltage: U0/U(Um): 19/33(36)kV.

U0—Rated power frequency voltage between earth and metal shield to conductor for cable design;

U—Rated power frequency voltage among conductors for cable design;

Um—Bearable max value of “Max System Voltage” for equipment.

2.Max conductor operating temperature at normal operation: 90℃ for XLPE insulation.

3.Max conductor temperature during cable short circuit: 250℃ for XLPE insulation (max. duration is 5 sec.)

4.Min. bending radius of cable during installation:

(1)Single-core cable: 15D.

(2)Multi-core cable: 12D.

D—Actual O.D of cable sample (mm)

5 .Cable Installation

The ambient temp of cable installation shall not be less than 0℃, the cable shall be preheated if it is less than 0℃.

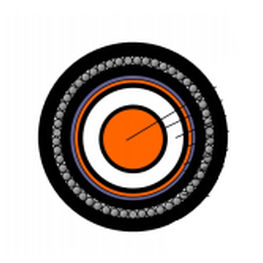

Cable structure

1. Conductor: category stranded copper conductor as per BS EN/IEC 60228.

2. Conductor screen: semi-conducting screen material.

3. Insulation: XLPE type GP8 as per BS 7655.

4. Insulation screen: semi-conducting screen material.

5. Metallic screen: copper tape or wire screen as per BS 6622.

6. Filler: polypropylene nets PP strip.

7. Wrapping tape: non-woven fabrics.

8. Separating sheath: PVC type 9 as per BS 7655.

9. Armor: aluminum wire for single-core cable, steel wire for multi-core cable.

10. Outer sheath: PVC type 9 as per BS 7655.

Catalogs

No catalogs are available for this product.

See all of Sunway Company‘s catalogsRelated Searches

- Electrical cable

- Copper cable

- Copper electrical cable

- Power cable

- Multi-strand cable

- Stranded electrical cable

- PVC-sheathed cable

- IEC electrical cable

- PVC-sheathed electrical cable

- Single-conductor cable

- Single-core electrical cable

- DIN electrical cable

- Distribution cable

- Aluminum cable

- Distribution electrical cable

- Aluminum electrical cable

- XLPE-insulated cable

- XLPE-insulated electrical cable

- Multi-core electrical cable

- Overhead electrical cable

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.