- Materials - Tools - Components

- Semi-finished products

- Tungsten carbide

- Surface Engineering Alloy Co.

- Products

- Catalogs

- News & Trends

- Exhibitions

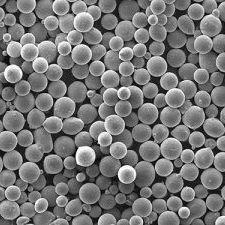

Tungsten carbide

Add to favorites

Compare this product

Description

Surface Engineering’s Carboride Hardfacing products are designed to resist severe abrasion in combination with excellent corrosion resistance, adhesive wear resistance, erosion resistance, and high temperature resistance up to 1100° Fahrenheit.

The deposits contain up to 65% Fused Tungsten Carbide in Nickel-Chrome-Silicon-Boron matrices ranging in hardness from Rc18 to 62 for variances in toughness and impact requirements. These self-fluxing alloys containing Boron provide for high bond strengths between the We particles and the matrix eliminating wear caused by the release of the hard We particles upon impact. The composites provide for easy of weldability and the deposits are smooth and uniform. Our Carboride products may be applied by GTAW, SMAW, PTA, Oxy-Acetylene, Spray & Fuse, Manual Torch, and our most popular composition of 40% Nickel-ChromeBoron and 60% Tungsten Carbide is even available in in the form of MIG wire.

Surface’s Carboride product compositions are designated by five (5) digit numbers, whereas the first two digits indicate the percentage of matrix, the second two indicate the percentage of Tungsten Carbide, and the last digit indicates the matrix hardness. Hence, Carboride 40606 would be a composition of 40% Re 60 NiCrSiB and 60% Tungsten Carbide. Compositions may be customized to suit individual application requirements. Contact our Customer or Technical Service Departments for more information.

Other Surface Engineering Alloy Co. products

Consumables

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.