- Production Machines

- Cutting Machine

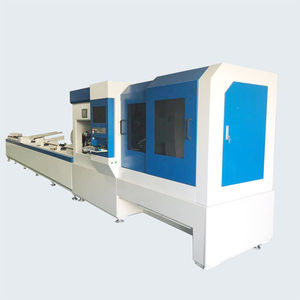

- Fiber laser cutting machine

- SUZHOU CHANXAN LASER TECHNOLOGY CO., LTD.

Fiber laser cutting machine CW-J seriesfor metalsheet metalCNC

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Material

- for metal

- Product handled

- sheet metal

- Control type

- CNC

- Applications

- for industrial applications, for metal fabrication

- Other characteristics

- automatic, high-precision

- X travel

2,500 mm

(98.43 in)- Y travel

1,325 mm

(52.17 in)- Z travel

100 mm

(4 in)- Cutting speed

20,000 mm/min

(13.123 in/s)- Repeatability

0.03 mm

(0.0012 in)- Overall length

3,800 mm

(150 in)- Overall width

1,850 mm

(73 in)- Height

1,300 mm

(51 in)- Weight

1,700 kg

(3,747.86 lb)

Description

The fiber laser cutting machine are widely used in auto manufacturing, rail, chassis cabinets, elevators, household appliances, kitchenware. lamps, hardware, advertising. aviation, aerospace, instrumentation. ships, metallurgical equipment. jewelry, tools, decoration, metal processing , And other industries which need sheet metal processing.

More efficiency and less power consumption

The increased electrical efficiency of fiber laser technology drastically slashes the electrical consumption of the system which means a monthly savings on your utility bills and a reduction in the initial investment in electrical equipment and services.

No laser maintenance needed

The fiber laser does not require routine maintenance or rebuilding procedures. No laser gas is needed. Laser beam quality is stable over time and is available immediately upon start up.

Superior performance on thinner materials

The faster speed of nitrogen fiber laser cutting on thin walled more than doubles machine productivity compared to CQ: mild steel and medium thickness stainless steel are the materials that typically benefit the most from fiber laser technology.

New materials and new opportunities

Copper and brass, materials which were off-limits with C02 technology can be easily cut with fber laser. Even tricky to cut aluminum and galvanized steels have no limits. Fiber technology offers new opportunities and a more robust production method

VIDEO

Other SUZHOU CHANXAN LASER TECHNOLOGY CO., LTD. products

Metal Laser Cutting Machine

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Plastic cutting system

- Precision cutting system

- Fabric cutting system

- Aluminum cutting system

- SS cutting machine

- Sheet cutting system

- Metal fabrication cutting system

- Cutting machine for the automotive industry

- High-performance cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.