- Production Machines

- Cutting Machine

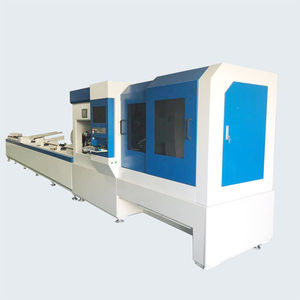

- Fiber laser cutting machine

- SUZHOU CHANXAN LASER TECHNOLOGY CO., LTD.

Fiber laser cutting machine CX-2030J-Cfor aluminumfor stainless steelfor steel

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Material

- for aluminum, for stainless steel, for steel, for carbon steel, for copper, for brass, for titanium

- Product handled

- sheet metal, tube

- Control type

- CNC

- Applications

- for industrial applications

- Other characteristics

- automatic, high-precision, rack-and-pinion, with exchange table, alloy steel

- X travel

6,000 mm

(236.22 in)- Y travel

1,500 mm, 2,000 mm

(59.06 in, 78.74 in)- Cutting speed

130,000 mm/min

(85.302 in/s)- Laser power

Min.: 3,000 W

Max.: 10,000 W

- Repeatability

0.02 mm

(0.0008 in)

Description

The machine is equipped with stable opticalsystem and control system, CNC system esp. for laser cutting, servo motor, high-precision rack and gear system, imported original packaged fifiber laser to ensure more stable cutting performance and longer life. Annealing process eliminates stress, increases the extension of the body. The machine body is solid and stable to ensure the stability and reliability during working. The operating system is user friendly and provides better interaction between operator and machine. Gorgeous graphical interface controllable with mouse, nice designed and easy to learn.

Cost saving for its maximum material utilization and molding free features.

High rigidity with strengthening welded bed and secondary annealing so the mechanical stress is reduced.

High efficiency, the exchange platform doubles the cutting efficiency and maximizes the time and manpower.

High reward for its fast speed cutting to increase product added value and long life. It will bring double return to your investment.

Easy to operate, high cutting precision, scientific typesetting, and more material saving.

1.Application Materials

Fiber Laser Cutting Equipment is suitable for metal cutting with Stainless Steel Sheet, Mild Steel Plate, Carbon Steel Sheet, Alloy Steel Plate, Spring Steel Sheet, Iron Plate, Galvanized Iron, Galvanized Sheet, Aluminum Plate, Copper Sheet, Brass Sheet, Bronze Plate, Gold Plate, Silver Plate, Titanium Plate, Metal Sheet, Metal Plate, Tubes and Pipes, etc

Other SUZHOU CHANXAN LASER TECHNOLOGY CO., LTD. products

Metal Laser Cutting Machine

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Cutting machine for industrial applications

- Automatic cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Plastic cutting system

- Precision cutting system

- Fabric cutting system

- Aluminum cutting system

- SS cutting machine

- Sheet cutting system

- Metal fabrication cutting system

- Cutting machine for the automotive industry

- High-performance cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.