- Production Machines

- Cutting Machine

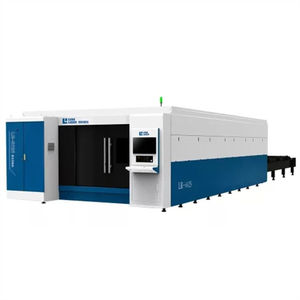

- Laser cutting machine

- Suzhou Lead Laser Technology Co.,Ltd.

Laser cutting machine Excalibur 3015 for metalsheet metalCNC

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Material

- for metal

- Product handled

- sheet metal

- Control type

- CNC

- Configuration

- gantry type

- Other characteristics

- precision, linear

- X travel

3,050 mm

(120.08 in)- Y travel

1,530 mm

(60.24 in)- Z travel

100 mm

(4 in)- Laser power

Max.: 20,000 W

Min.: 3,000 W

Description

Precision CNC laser cutting machine -Excalibur 3015 Laser Cutting is an all-purpose gantry type flying optics CNC laser cutting machine. After two years developed by professional foreign team, reasonable mechanical structure and global first class key components make the machine running almost perfect performance. Dual linear guide at each side supports enough to motor, which greatly guarantee the mechanical features and high precision for products during very high speed cutting. Thanks to high level motor driven, the acceleration can up to 3G. It can compete with any global laser cutting machine.

-

High strength cast Aluminum bridge

Whether the machine can running well depends on the weight of bridge. As we all know, Aluminum is the less weight compare with other material. This new design after analysis by software, it can not only be light but also durable.

Features

On-board database with cutting and piercing parameters for all materials and thicknesses

On-line correction of cutting and piercing parameters during processing

Skeleton cutting function, to cut off the remains of a sheet in a fast and efficient way

Graphical restart at any point by a simple mouse-click on the part geometry where a restart is required

Automatic micro-joints can be added to the program on the machine

Automatic calibration of distance sensor and servo cutting gas valve

Adaptive corner pulse and laser power modulation for optimum cutting

results in sharp corners and on special geometries

Lead-in transition function to establish a stable cutting after the piercing procedure by having a smooth change of cutting parameters along the lead-in

Other Suzhou Lead Laser Technology Co.,Ltd. products

CNC Laser Cutting Machine

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Automatic cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Precision cutting system

- Sheet cutting system

- CE cutting system

- High-performance cutting system

- Compact cutting system

- Bridge cutting system

- Cutting machine with automatic loader

- High-power cutting machine

- Gantry type cutting system

- Economical cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.