- Production Machines

- Cutting Machine

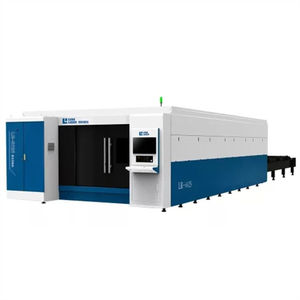

- Laser cutting machine

- Suzhou Lead Laser Technology Co.,Ltd.

Laser cutting machine LZ seriesfor metalsheetbridge

Add to favorites

Compare this product

Characteristics

- Technology

- laser

- Material

- for metal

- Product handled

- sheet

- Configuration

- bridge

- Other characteristics

- high-precision, high-speed

- X travel

6,050 mm, 8,050 mm

(238.19 in, 316.93 in)- Y travel

2,550 mm

(100.39 in)- Z travel

310 mm

(12 in)- Laser power

Min.: 4,000 W

Max.: 12,000 W

Description

High speed laser cutting machine LEAD LZ 6025/8025. When choosing laser machine, most customer pay more attention on the speed of cutting machine, which will definitely show how's efficiency. We provide LEAD LZ 6025/8025 to realize 150m/min in single X/Y axes. Z acceleration can up to 2g. When matching with high power over 8kw, the piercing time of 25mm carbon steel is within 0.1 secs. The available size in 6 meters and 8meters for variable compatible metal sheet with size in 3meters,4meters .

Main Feature

The machine has a robust and rigid design that guarantees repeatable high precision cutting results

Both the working tables moves in and out of the machine simultaneously, decreasing dramatically the time of the table change cycle and increasing the productivity of the machine. New sheets get faster in and cut sheets get faster out of the machine

The machine features completely closed cabin and offers safe and ergonomic operation. The large eye-safe windows allow an optimal overview of the entire working area of the machine.

The light-weight bridge assures accurate cutting results even under high-dynamic axis movements

A long vertical stroke of the cutting head gives additional freedom in the cutting application: pre-formed sheets, tubes, profiles, etc. can easily be put on the cutting table and are in reach of the cutting head.

The machine lay-out is symmetric when it comes to the maintenance access from the sides: either side can be put close to a wall while having all the necessary reach to maintenance points on the opposite site.

Other Suzhou Lead Laser Technology Co.,Ltd. products

CNC Laser Cutting Machine

Related Searches

- Cutting system

- Metal cutting system

- CNC cutting system

- Laser cutting system

- Automatic cutting system

- High-precision cutting system

- Sheet metal cutting system

- High-speed cutting system

- Fiber laser cutting system

- Tube cut-off machine

- Precision cutting system

- Sheet cutting system

- CE cutting system

- High-performance cutting system

- Compact cutting system

- Bridge cutting system

- Cutting machine with automatic loader

- High-power cutting machine

- Gantry type cutting system

- Economical cutting system

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.