- Production Machines

- Cutting Machine

- Fiber laser cutting machine

- Suzhou Suntop Laser Technology CO.,LTD

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

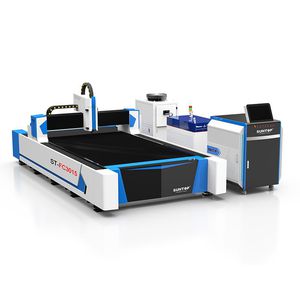

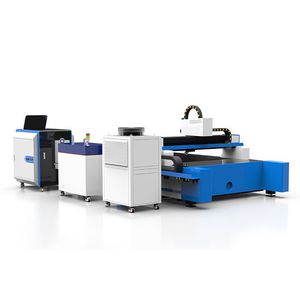

Fiber laser cutting machine ST- FC8025-3000Rfor metalsheet metalfor thin sheet metal

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Material

- for metal

- Product handled

- sheet metal, for thin sheet metal

- Control type

- CNC

- Other characteristics

- high-precision, high-speed

- X travel

2,550 mm

(100.39 in)- Y travel

8,100 mm

(318.9 in)- Cutting speed

Min.: 900 mm/min

(0.591 in/s)Max.: 35,000 mm/min

(22.966 in/s)- Laser power

2,000 W, 3,000 W, 4,000 W, 6,000 W, 10,000 W

Description

1. Machine general introduction

Fiber laser cutting is the fastest process for thin sheet metal, it adopt the imported fiber laser source, long lifetime, fast and high precision cutting speed than the traditional plasma cutting or water jet cutting method,for high reflective materials like aluminium,copper and brass can be cut with ease,parts process cost is very low, Little to no maintenance costs, the consumable part cost is low,the only parts that need to be changed are nozzles and protection lens over long periods.

2. Machine main features:

♦The double rack and pinion driving system and imported open-type CNC system enable high processing accuracy and high working efficiency during high speed cutting.

♦ Standard collocation of 500W fiber laser generator and optional 500W 750w, 1000W 2000W IPG or Raycus or SPI fiber laser generator ensures low operation and maintenance cost, the Open structure is easy and convenient for material uploading and unloading.Drawer collecting device makes receiving materials more convenient.

♦Aiming at high speed cutting, we design and manufacture strengthened welded machine body after 2 times of aging process which ensures long-term accuracy and stability of performance,standard collocation of dual-pressure gas control system of 3 gas sources (high pressure air, nitrogen, oxygen) meets the processing requirement of all kinds of materials. Easy operation and low cost

Catalogs

No catalogs are available for this product.

See all of Suzhou Suntop Laser Technology CO.,LTD‘s catalogsOther Suzhou Suntop Laser Technology CO.,LTD products

Fiber Laser Cutting Machine-Single Table

Related Searches

- SUNTOP cutting machine

- SUNTOP metal cutting machine

- SUNTOP CNC cutting machine

- SUNTOP laser cutting machine

- SUNTOP cutting machine for industrial applications

- SUNTOP automatic cutting machine

- SUNTOP high-precision cutting machine

- SUNTOP sheet metal cutting machine

- SUNTOP high-speed cutting machine

- SUNTOP fiber laser cutting machine

- SUNTOP tube cutting machine

- SUNTOP plastic cutting machine

- SUNTOP precision cutting machine

- SUNTOP fabric cutting machine

- SUNTOP aluminum cutting machine

- SUNTOP stainless steel cutting machine

- Sheet cutting system

- SUNTOP metal fabrication cutting machine

- SUNTOP cutting machine for the automotive industry

- SUNTOP CE cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.