- Production Machines

- Cutting Machine

- Fiber laser cutting machine

- Suzhou Suntop Laser Technology CO.,LTD

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

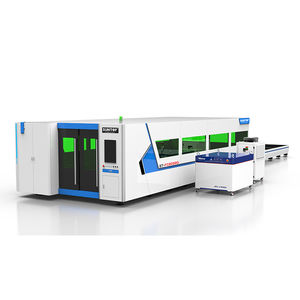

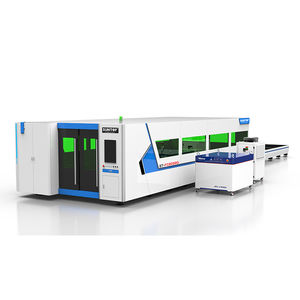

Fiber laser cutting machine ST-FC6020-3000Ffor metalfor carbon steelsheet metal

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser

- Material

- for metal, for carbon steel

- Product handled

- sheet metal, door frame, for thick sheet metal, for metal pipes, for thin sheet metal, for door

- Control type

- CNC

- Applications

- for aeronautical applications, for industrial applications, for the automotive industry, for metal fabrication, for the electronics industry, for shipbuilding, for medical applications

- Configuration

- 3-axis

- Other characteristics

- automatic, high-precision, high-speed, precision, CE, high-performance, for steel construction, for large parts, for mass production, heavy-duty

- X travel

2,050 mm

(80.71 in)- Y travel

6,100 mm

(240.16 in)- Cutting speed

Min.: 700 mm/min

(0.459 in/s)Max.: 32,000 mm/min

(20.997 in/s)- Laser power

1,000 W, 2,000 W, 3,000 W, 6,000 W, 10,000 W

Description

Electro-optical conversion efficiency ( power saving):

The optical fiber as the laser medium, the optical conversion efficiency of pump light energy in to common wavelength material processing (1069-1090nm) up to 50%; the total electro-optic commonly of fiber laser conversion efficiency up to 30% or more, more higher than carbon dioxide glass(15-20%), (6-10%) for carbon dioxide radio frequency laser (6-10%), comparative data: lamp-pumped cutting machine 650W total power is about 30KW/hour,the total power of the 800W fiber laser cutting machine is not more than 8KW, you can calculate how many power cost you can save one year.

Maintenance-free (low maintenance costs):

All-fiber laser optical path entirely composed of fibers and fiber-optic components, welding technology using optical fiber connection between the optical fiber and fiber optic components, the entire optical path is completely enclosed in the optical fiber waveguide. Once this natural all closed optical path is formed, without additional isolation measures can be self-contained, isolated from the external environment to achieve. Resonator fiber grating replaces the lens structure, there is no lens contamination, distortion and so on, so that in case of proper use of fiber lasers, basically no maintenance.

Catalogs

No catalogs are available for this product.

See all of Suzhou Suntop Laser Technology CO.,LTD‘s catalogsOther Suzhou Suntop Laser Technology CO.,LTD products

Fiber Laser Cutting Machine-Full Enclosed

Related Searches

- SUNTOP cutting machine

- SUNTOP metal cutting machine

- SUNTOP CNC cutting machine

- SUNTOP laser cutting machine

- SUNTOP cutting machine for industrial applications

- SUNTOP automatic cutting machine

- SUNTOP high-precision cutting machine

- SUNTOP sheet metal cutting machine

- SUNTOP high-speed cutting machine

- SUNTOP fiber laser cutting machine

- SUNTOP tube cutting machine

- SUNTOP plastic cutting machine

- SUNTOP precision cutting machine

- SUNTOP fabric cutting machine

- SUNTOP aluminum cutting machine

- SUNTOP stainless steel cutting machine

- Sheet cutting system

- SUNTOP metal fabrication cutting machine

- SUNTOP cutting machine for the automotive industry

- SUNTOP CE cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.