- Production Machines

- Cutting Machine

- CO2 laser cutting machine

- Suzhou Suntop Laser Technology CO.,LTD

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

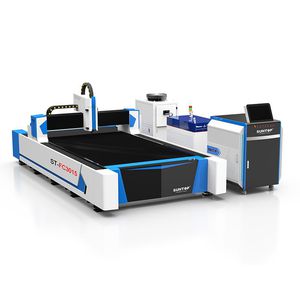

Fiber laser cutting machine ST- FC12025-15000RCO2 laserfor metalCNC

Add to favorites

Compare this product

Characteristics

- Technology

- fiber laser, CO2 laser

- Material

- for metal

- Control type

- CNC

- Configuration

- compact

- Other characteristics

- high-precision, high-speed

- X travel

2,550 mm

(100.39 in)- Y travel

12,100 mm

(476.38 in)- Cutting speed

Max.: 38,000 mm/min

(24.934 in/s)Min.: 500 mm/min

(0.328 in/s)- Laser power

3,000 W, 4,000 W, 6,000 W, 10,000 W, 15,000 W

Description

1) Machine Stable running: adopting the top world import fiber lasers, stable performance, and key parts can reach 100,000 hours, high efficiency for photoelectric conversion: Compare with CO2 laser cutting machine, fiber laser cutting machine has three times photoelectric conversion efficiency,the most advanced Europed laser source with high photoelectric conversion efficiency rate up to 30%, the lifetime of the key parts can reach 100,000 hours, machine no maintenance, no consumable parts.

2) Machine Low running cost: Save energy and protect environment, low maintenance: fiber line transmission no need reflect lens, save maintenance cost, World famous brand laser cutting head, ensure good cutting effects and high precision.

3) Easy operations: fiber line transmission, no adjustment of optical path, super flexible optical effects: compact design, compact and easy to flexible manufacturing requirements, economic price but top quality, especiall for Advertising industry.

4) highly strengthened steel bed annealed to ensure high speed with no deformation at least 20 years.

5) Precise rack bilateral servo motor driving system with highest response speed, machine idel travel speed up to 100 meters/min.

2. Machine main features:

German high performance reducer, gear and rack transmission which ensure the cutting precision and the stable performance, our 800W CNC fiber laser cutting equipment uses a moving gantry structure, imported high-precision screw and linear guide, smooth transmission, high precision , the X, Y, Z axes are imported from Japan servo motor, high-precision, high- speed, high-torque, high inertia, stable performance and durable.

Catalogs

No catalogs are available for this product.

See all of Suzhou Suntop Laser Technology CO.,LTD‘s catalogsOther Suzhou Suntop Laser Technology CO.,LTD products

Fiber Laser Cutting Machine-Single Table

Related Searches

- SUNTOP cutting machine

- SUNTOP metal cutting machine

- SUNTOP CNC cutting machine

- SUNTOP laser cutting machine

- SUNTOP cutting machine for industrial applications

- SUNTOP automatic cutting machine

- SUNTOP high-precision cutting machine

- SUNTOP sheet metal cutting machine

- SUNTOP high-speed cutting machine

- SUNTOP fiber laser cutting machine

- SUNTOP tube cutting machine

- SUNTOP plastic cutting machine

- SUNTOP precision cutting machine

- SUNTOP fabric cutting machine

- SUNTOP aluminum cutting machine

- SUNTOP stainless steel cutting machine

- Sheet cutting system

- SUNTOP metal fabrication cutting machine

- SUNTOP cutting machine for the automotive industry

- SUNTOP CE cutting machine

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.