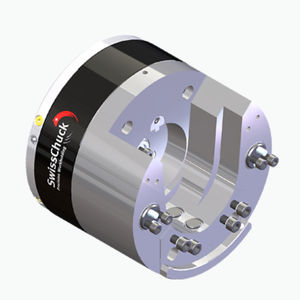

Floating workpiece clamping chuck SAP TO KCHPgrindingcylindricaladjustable

Add to favorites

Compare this product

Characteristics

- Clamping method

- floating

- Application

- grinding

- Other characteristics

- cylindrical, adjustable

- Number of jaws

- 3-jaw

- Clamping range

32 mm, 50 mm, 100 mm

(1.26 in, 1.97 in, 3.94 in)

Description

The concentric chucks of Type 3KCHP can be «converted» into a compensating chuck using an SAP kit. This design feature allows the machining between centers of critical shaft-type workpieces. The floating clamping ring ensures that the workpieces are not subject to any deformation due to clamping forces. A further advantage offered by this arrangement is that the concentric chucks do not have to be dismounted and replaced by a standard compensating chuck.

Function & Field of Application

Standard accessory to the KCHP/VKCHP precision power chucks

• Floating driving dog for shaft-type components clamped between centers

• Suitable for long and thin shaft-type workpieces

• Suitable for both manual and automated processes

• Adjustable in clamping force and for different clamping diameters

Advantages

• Fast retooling of the KCHP/VKCHP between centric clamping and for grinding between centers

• The KCHP does not need to be dismounted for between-center operation

• No deformation when clamping long and thin shaft-type workpieces

• Highest precision when grinding between centers

• Individual clamping rings and clamping shoes are available upon request, custom-made to your specific workpieces

SAP Standard Kit – The optimal addition to your KCHP

Our SAP standard kits offer an optimal setup solution if you want to use your grinding machine as flexibly as possible and require grinding operations between centers. The SAP tooling can be mounted to the existing interface of the KCHP/VKCHP. The centering point on the chuck can be aligned to micrometer precision utilizing adjusting screws.

Catalogs

PRECISION POWER CHUCK KCHP/VKCHP

12 Pages

PRECISION POWER CHUCK

12 Pages

Related Searches

- Chuck

- Collet chuck

- Drilling chuck

- High-precision chuck

- Magnetic chuck

- Power chuck

- 3-jaw turning chuck

- High-speed chuck

- Workpiece clamping chuck

- Machining collet chuck

- Lathe turning chuck

- Machining turning chuck

- Permanent magnet magnetic chuck

- Precision turning chuck

- Through-hole turning chuck

- Radial chuck

- Manual tightening chuck

- Mandrel

- 3-jaw workpiece clamping chuck

- Precision workpiece clamping chuck

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.