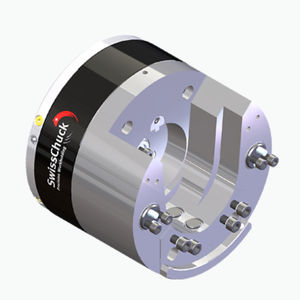

Grinding workpiece clamping chuck OVEKAhigh-precisioncylindricalpin

Add to favorites

Compare this product

Characteristics

- Application

- grinding

- Other characteristics

- hydraulic, high-precision, cylindrical, pin

- Number of jaws

- 3-jaw, 4-jaw, 2-jaw

- Rotational speed

1,000 rpm, 1,500 rpm, 2,000 rpm, 3,000 rpm

(6,283 rad.min-1, 9,425 rad.min-1, 12,566 rad.min-1, 18,850 rad.min-1)

Description

The workpiece is generally ground between centers for centric cylindrical, orbital pin, or form grinding of complex shaft-type components. The challenge faced by the workholding device is to transfer the necessary torque, and thus the rotational movement to the workpiece, without deforming it by excessive lateral loads. SwissChuck's high-precision OVEKA/KA compensating chucks have been originally designed for the machining of crankshafts, a task for which they have amply proven themselves. Over the years, these chucks have undergone continuous improvements such that today, they are perfectly suited for grinding all shaft-type workpieces. Our compensating chucks are available in 2-, 3-, or 4-jaw versions.

Functions & Fields of Application

• 2-, 3- and 4-jaw versions are available in varied sizes

• Mostly intended for grinding machines

• Special versions available for combined grinding and hard-turning operations

Advantages

• With a patented circulating lubrication system (OVEKA)

• Highly sensitive hydraulic compensation

• Sealed chuck

• Small design height

• Very low maintenance

• 10-year warranty

Effortless compensation of workpiece-related concentricity errors in the clamping area!

The clamping devices are designed so that the effective clamping force is only fully applied when all clamping jaws are in contact with the clamping point. The highly sensitive compensation easily compensates workpiece-related concentricity errors in the area of the clamping point. The compact design allows optimum utilization of the machine-side center-to-center distance.

Catalogs

OVEKA & KA

8 Pages

COMPENSATING CHUCKS

8 Pages

Related Searches

- Chuck

- Collet chuck

- Drilling chuck

- High-precision chuck

- Magnetic chuck

- Power chuck

- 3-jaw turning chuck

- High-speed chuck

- Workpiece clamping chuck

- Machining collet chuck

- Lathe turning chuck

- Machining turning chuck

- Permanent magnet magnetic chuck

- Precision turning chuck

- Through-hole turning chuck

- Radial chuck

- Manual tightening chuck

- Mandrel

- 3-jaw workpiece clamping chuck

- Precision workpiece clamping chuck

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.