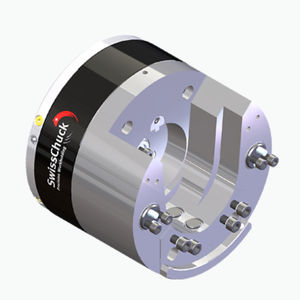

Hydraulic workpiece clamping chuck OVEKAVgrinding3-jaw4-jaw

Add to favorites

Compare this product

Characteristics

- Application

- grinding

- Other characteristics

- hydraulic

- Number of jaws

- 3-jaw, 4-jaw, 6-jaw, 2-jaw

- Rotational speed

400 rpm, 500 rpm, 3,500 rpm, 5,000 rpm

(2,513 rad.min-1, 3,142 rad.min-1, 21,991 rad.min-1, 31,416 rad.min-1)

Description

The clamping systems for grinding machines are designed for shaft-type workpieces between centers. These main chucks consist of a two-part base unit design with a center point and a displaceable compensating jaw chuck. The workpieces are held between centers and clamped, with compensation, by the extended jaw chuck. In this position, The workpieces are then ground in this position. When open, the chuck can be moved back against the spindle by up to 50 mm. This movement releases the previous clamping point, which can also be ground. Here, the workpiece drive is realized either by frictional engagement between the center point and the workpiece or by a driver which can engage the workpiece. With these clamping systems, workpieces can thus be completely finished-ground in one clamping operation.

Functions & Fields of Application

• Hydraulically actuated compensating chuck for clamping between centers

• Displaceable chuck

• 2-, 3-, 4- and 6-jaw versions in varied sizes

• In the main, designed for grinding machines

• Special versions for combined operations of grinding and hard-turning operations

Advantages

• Hydraulic compensation

• Patented oil circulating lubrication

• Maintenance-free

• The axial displacement allows the grinding of the initial clamping position

• Length of displacement up to 100 mm

With patented circulating lubrication!

The hydraulically actuated chuck series OVEKAV is equipped with the patented EP1 190 815 circulation lubrication. All internal chuck components are actively lubricated during each clamping process. With virtually maintenance-free chucks, this results in minimal lifecycle costs.

Catalogs

Related Searches

- Chuck

- Collet chuck

- Drilling chuck

- High-precision chuck

- Magnetic chuck

- Power chuck

- 3-jaw turning chuck

- High-speed chuck

- Workpiece clamping chuck

- Machining collet chuck

- Lathe turning chuck

- Machining turning chuck

- Permanent magnet magnetic chuck

- Precision turning chuck

- Through-hole turning chuck

- Radial chuck

- Manual tightening chuck

- Mandrel

- 3-jaw workpiece clamping chuck

- Precision workpiece clamping chuck

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.