- Machine-tools

- Machine Tool Accessory

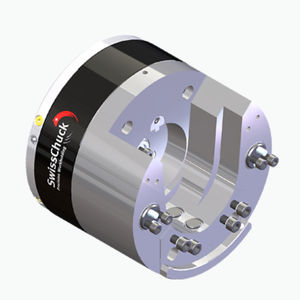

- Power chuck

- SwissChuck AG

Power chuck Triton® series3-jawquick-changelathe

Add to favorites

Compare this product

Characteristics

- Type

- automatic

- Number of jaws

- 3-jaw

- Other characteristics

- quick-change, lathe, machining, precision, through-hole, self-centering, pull-back, for small parts, steel, high-speed, high-precision, for machining round parts, power-operated, for shaft

- Gripping force

12 kN, 35 kN, 55 kN, 80 kN

- Outer diameter

165 mm, 220 mm, 290 mm, 370 mm

(6 in, 9 in, 11 in, 15 in)

Description

With Triton®, SwissChuck AG has introduced a modular power chuck range that caters to high-end applications such as turning, hard turning, and grinding. Precision manufacturing and high-quality materials components guarantee a radial runout of less than 5 µm. The precision interfaces between the base and top jaws ensure a fast change-over of the accessory parts and guarantee constant chucking repeatability, eliminating subsequent turning or regrinding of the top jaws. The extended version, Triton® PLUS, additionally features centrifugal force compensation and thus guarantees constant chucking force at high RPM, specifically when dealing with hard turning.

Function & Fields of Application

• Radial runout ≤ 0.005 mm

• Accuracy of jaw change over ≤ 0.002 mm

• No need for regrinding clamping faces after jaw change-over

• Completely sealed off and low maintenance

• Jaws can be changed between chucks of the same design

• Reinforces jaw interface for high material removal rate

• Offers a wide range of applications; a chuck for turning, hard-turning, and grinding

Advantages

• Sealed, suitable for applications on lathes and grinding machines

• Precision interface between the base and top jaws

• Optional centrifugal force compensation, Triton® PLUS version for high RPM turning operations

• Standard accessories available

• Large through-hole, bar feeding option possible

Changing jaws within micrometer tolerances is made easy!

All power chucks of the Triton® generation feature precision jig-ground locating bores for precision ball positioning. This design feature ensures a quick clamping jaw change, independent of the chuck, without regrinding the jaws.

Catalogs

No catalogs are available for this product.

See all of SwissChuck AG‘s catalogsRelated Searches

- Chuck

- Collet chuck

- Drilling chuck

- High-precision chuck

- Magnetic chuck

- Power chuck

- 3-jaw turning chuck

- High-speed chuck

- Workpiece clamping chuck

- Machining collet chuck

- Lathe turning chuck

- Machining turning chuck

- Permanent magnet magnetic chuck

- Precision turning chuck

- Through-hole turning chuck

- Radial chuck

- Manual tightening chuck

- Mandrel

- 3-jaw workpiece clamping chuck

- Precision workpiece clamping chuck

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.