- Products

- Catalogs

- News & Trends

- Exhibitions

Laser diffraction particle size analyzer MYTOSprocessfor powdersin-line

Add to favorites

Compare this product

Characteristics

- Technology

- laser diffraction

- Applications

- process

- Other characteristics

- for powders, in-line

Description

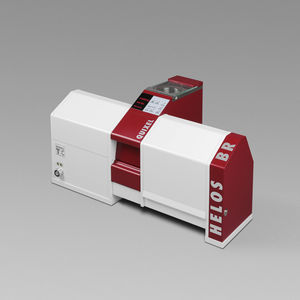

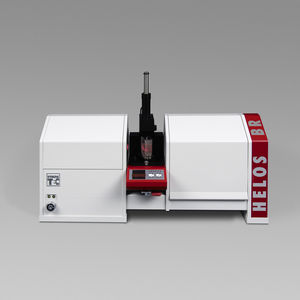

MYTOS integrates the established core technologies of HELOS laser diffraction and RODOS dry dispersion in a single robust body: a process-proven laser diffraction sensor for dry powders ranging from 0.25 µm to 3,500 µm.

In combination with continuously operating sampling system TWISTER a complete integration into the processing pipe is realised making it a true in-line solution delivering representative results. Alternatively, MYTOS may be operated on-line either with TWISTER, MIXER, SCREWSAMPLER, L-probes or existing sampling solutions. Integrated at-line operation in automated lab environments is succeeded with vibratory feeder VIBRI. For instance, typical applications comprise milling operations or spray granulation.

The process-specific laser diffraction sensors find a wide range of applications from cement to pharmaceuticals, from roughest industrial conditions to GMP environments. If required, both systems may be configured for ATEX zones.

Advantages:

•Final product quality monitored via closed control loop system

•Assrance of high batch-to-batch consistency

•Greater insight into and control of manufacturing processes

•Real time measurement of critical quality attributes in-process

•Reduction of noncompliant batches and rejects

•Long system service life with low maintenance requirements

Other Sympatec GmbH products

Particle Size Analyzer with Laser Diffraction

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.