PS thermoforming machine ARCIL DN200for cup productionautomaticcompact

Add to favorites

Compare this product

Characteristics

- Type

- PS

- Applications

- for cup production

- Operational mode

- automatic

- Other characteristics

- compact

Description

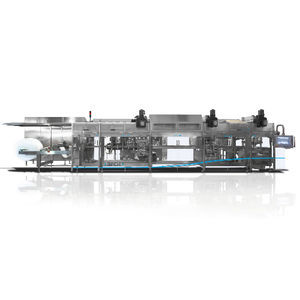

ARCIL DN200 THERMOFORMING MACHINE

Compact and affordable, our DN200 is designed to streamline your production process, our equipment offers unparalleled ease-of-use and efficiency, making it ideal for small-scale operations and product tests. With a capacity of up to 5,400 cups/hour or 10,800 mini-portions/hour, the DN200 is optimal for industries where flexibility and affordability are critical.

ARCIL FORM-FILL-SEAL EXPERIENCE

Easy Operation and Reliability

Our machine is engineered for ease of use and utmost reliability, ensuring smooth operations at all times.

Versatility

From yogurt and dairy desserts to sauces and jellies, the DN200 can handle a wide range of products, thanks to its capability to thermoform different kinds of cups and trays.

Flexible Material Compatibility

Whether it's PS, PET or multilayer materials, our machine can accommodate various packaging materials to meet your specific requirements.

Ultra-Compact Design

With its small footprint, the DN200 saves valuable floor space while maximizing productivity.

Productivity Boost

Experience enhanced productivity with fast format and product switches, minimizing downtime and optimizing efficiency.

HEALTH AND SAFETY STANDARDS

Our equipment complies with food industry standards. It is an extremely clean machine throughout its production stages (thermoforming, dosing, sealing and cutting)

The ARCIL DN200 unit is prepared for CIP (Clean-In-Place), while the dosing area is protected against foreign contaminants

Thermoforming materials are subject to rigorous cleaning and sterilization processes that allow us to ensure high health standards for each product

VIDEO

Catalogs

ARCIL DN200

2 Pages

Related Searches

- Packing machine

- Automatic packing machine

- Automatic filler

- Wrapping machine

- Liquid filler

- Filler for the food industry

- Automatic wrapping machine

- Bottle filler

- Food product filling machine

- Volumetric filler

- Multi-head filler

- Case packer

- Thermoformer

- Automated thermoforming machine

- Automatic case packer

- Weight filler

- Horizontal wrapping machine

- Compact filler

- Packaging thermoformer

- Wrapping machine with conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.