PS form-fill-seal machine ARCIL DP100for packagingautomaticcompact

Add to favorites

Compare this product

Characteristics

- Type

- PS

- Applications

- for packaging

- Operational mode

- automatic

- Other characteristics

- compact

Description

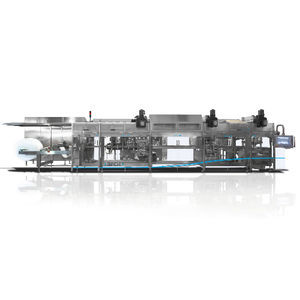

The ARCIL DP100 is a versatile Form-Fill-Seal (FFS) machine designed to meet the diverse packaging needs of cups and mini portions with a focus on a precise and clean filling. The DP100 can form both miniportions and larger cups, it can produce up to 21,600 mini-portions per hour, or up to 7200 cups per hour.

DESIGN FEATURES

The ARCIL DP100 is a compact machine, designed for space optimization while owning the full packaging production in house, from thermoforming to sealing. With a footprint of around 10 square meters in its standard configuration, the DP100 is built with performance.

Performance

Operating at a pace of 30 strokes per minute, the ARCIL DP100 delivers reliable performance. With a standard mold configuration of 2x6, it achieves a maximum output of 21,600 mini-portions per hour,or 7200 cups per hour.

Market Focus

The ARCIL DP100 serves industries such as spreadable cheese, butter, jams, honey, oil, dairy products and dressings. Its versatility and efficiency make it well-suited for businesses catering to these markets.

Dosing and Packaging Options

Featuring a dosing range of 10 - 30 ml for mini-portions and up to 1L for cups and tubs, the ARCIL DP100 offers flexibility to accommodate a variety of product requirements. Additionally, it supports multipack configurations, providing further options for packaging customization and enhancing product presentation.

TECHNICAL SPECIFICATIONS

The ARCIL DP100 is equipped to handle a variety of packaging materials, including PS, PET, PLA, PP, and multilayer compositions. This Form-fill-seal machine is conceived to allow configurations with and without cups labelling.

Catalogs

No catalogs are available for this product.

See all of SYNERLINK‘s catalogsRelated Searches

- Packing machine

- Automatic packing machine

- Automatic filler

- Wrapping machine

- Liquid filler

- Filler for the food industry

- Automatic wrapping machine

- Bottle filler

- Food product filling machine

- Volumetric filler

- Multi-head filler

- Case packer

- Thermoformer

- Automated thermoforming machine

- Automatic case packer

- Weight filler

- Horizontal wrapping machine

- Compact filler

- Packaging thermoformer

- Wrapping machine with conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.