- Packing - Handling - Logistics

- Conveying

- Conveyor roller

- Syntron Material Handling

- Products

- Catalogs

- News & Trends

- Exhibitions

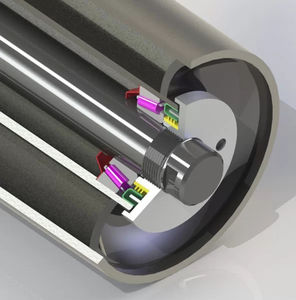

Conveyor roller E4000 series

Add to favorites

Compare this product

Description

The Link-Belt E4000 series idler line features factory lubricated and sealed-for-life rolls, which eliminate re-lubrication maintenance costs. The E4000 Idler line is also available with lubrication fittings at both ends of the idler for ease in field re-greasing from either side of the conveyor. Boasting load ratings exceeding CEMA E requirements, this idler line is designed for maximum capacity and continuous handling of most abrasive materials.

The design of the E4000 rollers, available in 36"-96" belt width 20, 35, and 45 degree troughed, positive action training, impact, and return idlers, extended, trouble free service life for your belt conveyor equipment. The series E4000 rollers, available in both 6" and 7" diameters, feature an exclusive, full length center tube and precision die-formed heads that are recessed into hot rolled mechanical shells. The entire unit is then continuously welded robotically, thus ensuring an integral, airtight unit wherein contaminants and corrosion cannot enter. This unrivaled center tube design guarantees perfect shaft/bearing alignment. Using solid, cold drawn steel shafts to minimize deflection and increase load ratings increases bearing life.

Series E4000HD heavy-duty idler assemblies are recommended where loads exceed CEMA E ratings. The heavy-duty stepped shaft design with standard 1-1/4" bearings will, in many cases, permit the conveying of loads up to 50% greater than the normal capacities. Available in 6" and 7" diameter rolls, the carrying idler’s external dimensions are identical to Series E4000. All series E4000HD heavy-duty idlers are available for belt widths up to 72".

Catalogs

No catalogs are available for this product.

See all of Syntron Material Handling‘s catalogsOther Syntron Material Handling products

Belt Conveyor Idlers

Related Searches

- Rail conveyor

- Transporting conveyor

- Belt conveyor

- Horizontal rail conveyor

- Conveyor for the food industry

- Feeder

- Inclined conveyor

- Vibration motor

- Materials handling conveyor

- Conveyor roller

- Bulk products conveyor

- Screw conveyor

- Transfer rail conveyor

- Vertical rail conveyor

- Vibrating feeder

- Compact conveyor

- Heavy load rail conveyor

- Electric vibration motor

- Bulk feeder

- Flexible conveyor

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.