- Power Transmission - Mechanical components

- Bearing and Linear Guide

- Tapered roller bearing

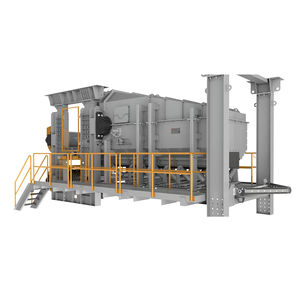

- Syntron Material Handling

- Products

- Catalogs

- News & Trends

- Exhibitions

Tapered roller bearing ball bearingcarbon steelfor mining and the metallurgical industry

Add to favorites

Compare this product

Characteristics

- Rolling element

- tapered roller, ball bearing

- Material

- carbon steel

- Applications

- for mining and the metallurgical industry

Description

Link-Belt® tapered bearing idler rolls are perfectly suited for continuous material handling operations moving massive volumes of tough, abrasive materials such as coal, iron ore, and rock products. Boasting load ratings that exceed CEMA requirements, this rugged line is available in CEMA D, E, and F series models. Each roller is equipped with a solid carbon steel shaft for minimum deflection under load, resulting in increased service life.

ADVANCED SEALING SYSTEM

Link-Belt sealed for life tapered roller bearing idlers feature factory-lubricated and sealed for life rolls which eliminates re-lubrication maintenance costs. They feature a triple lip rubber contact seal paired with a nylon deflector nut and integrated labyrinth seal that protects the precision tapered roller bearings in several ways. The outer deflector nut features a 90° contoured lip to deflect material away from the roll end. The triple lip contact seal and grease-filled labyrinth ensure against the ingress of performance-inhibiting contaminants.

MAXIMUM CORROSION PROTECTION

Link-Belt rolls are protected from corrosion by a polymeric powder coating baked on at high temperatures to provide resistance to abrasive elements. Outer adjusting nuts and assembly hardware are zinc-plated to minimize corrosion and ensure extended service.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Syntron Material Handling‘s catalogsOther Syntron Material Handling products

Underground Mining

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.