- Robotics - Automation - Industrial IT

- Automation

- Synventive Molding Solutions

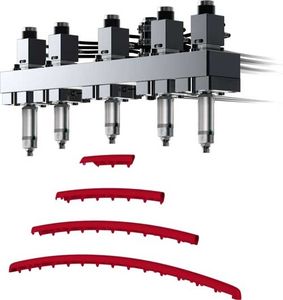

Valve control unit eGate®

Add to favorites

Compare this product

Characteristics

- Applications

- for valves

Description

eGate® electric valve gate hot runner systems feature patented technology to precisely control each valve pin’s position, acceleration, velocity and stroke allowing processors the unique ability to control the flow rate out of each nozzle gate at any time during the fill process. This technology is now available on all Synventive hot runner nozzle sizes.

eGate is ideally suited for injection molding applications that require precision, responsiveness and repeatability. Applications for eGate may include multi-shot/multi-material, sequential/cascading molding or for parts that require premium cosmetic surfaces. It is ideal for use in all electric and clean room environments.

eGate provides numerous advantages over traditional valve gates and is capable of delivering:

-Optimal cosmetics for class ‘A’ surfaces

-Superior molding flexibility

-Warpage reduction

-Clamp force reduction

-Part weight reduction

-Greater application flexibility

eGate brochure for medium to larger part applications.

eGate brochure for small part applications.

eGate Video for small part applications

Catalogs

No catalogs are available for this product.

See all of Synventive Molding Solutions‘s catalogsOther Synventive Molding Solutions products

Technologies

Related Searches

- Digital temperature control

- Temperature controller

- Digital temperature control unit

- Heating temperature control unit

- Programmable temperature control unit

- Industrial temperature control unit

- Compact temperature control

- Compact temperature control unit

- Modular temperature control

- Remote temperature control unit

- Standard temperature control unit

- Modular temperature control unit

- Vertical temperature controller

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.