Clean-in-place unit

Add to favorites

Compare this product

Description

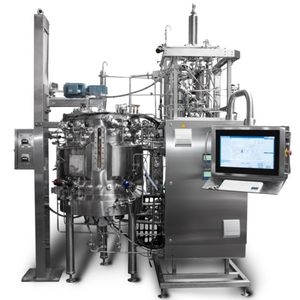

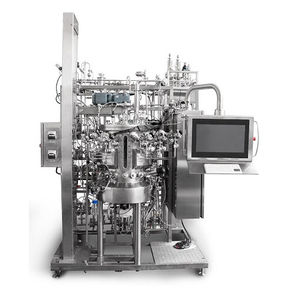

SYSBIOTECH engineering unit developed a fully automated stationary CIP-station for (bio)reactors, vessels and piping, which is currently available in standard version with tanks’ working volumes of 2×500 L.

Constructive design and reliability of our CIP-station not only ensures production of safe and quality products and increases their shelf life, but also reduces the costs of monitoring procedures for technological processes and products, increases the effectiveness of quality management systems, eliminating the need for operations to dismantle the removable parts and make connections in clean rooms.

Standard platform design (skid) allows for SIP/CIP functions for fermenters, bioreactors, piping or vessels with volumes from 2,000L up to 5,000L (depends on working volume of CIP tanks and configuration of processed vessel).

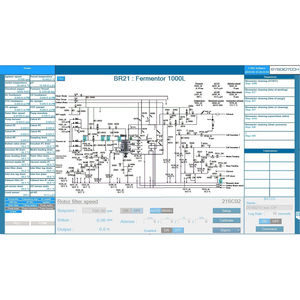

New C-BIO2™ operator and control platform provides enhanced functionality and process control options as well as full integration and connectivity to SYSBIOTECH’s Process Line equipment and third party (equipment) supervisory software, making it the ideal platform for the automation and data integration of your cleaning/sterilization process.

Catalogs

No catalogs are available for this product.

See all of SYSBIOTECH‘s catalogsRelated Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.