Milling tool holder MatrixEDM

Add to favorites

Compare this product

Characteristics

- Application

- milling

- Other characteristics

- EDM

Description

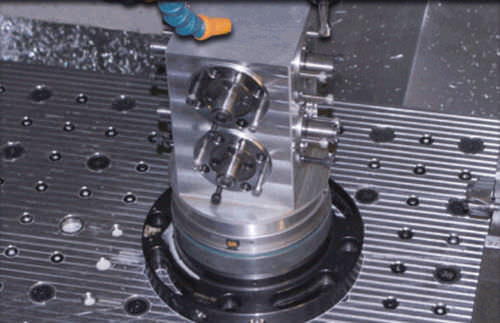

Measures to reduce the downtime of your machines are significantly more worth while than chasing seconds in the actual machining process. What matters is to keep the machines running. And that’s when you need an interface that gives fast setting-up.

The Matrix system is just that kind of interface. Setting-up in parallel away from the machine while it is working and then setting up in a matter of seconds in the stationary machine. Important for long runs, but crucial for the profitability of short runs or one-piece production.

The design has been optimised for metal-cutting machining and is ideal for work involving high machining forces. The generous diameter of the drawbar means short distances between the references and the applied locking force, giving maximum stability and accuracy. The inherent properties of the Matrix system truly come into their own in tough machining applications.

As well as extreme accuracy, Matrix features low construction height, ultra-precise indexing, a drawbar with through hole, and a broad range of pallets.

Features

• Repetition accuracy – within 0.002 mm.

• Drawbar with through hole – 69 mm

• Low Built-in height – 45 mm

• Locking force – 16 000 N

• Fixed index positions 4x90°

• All references hardened and ground

• Required air pressure, pneumatic chucks: 6±1 bar

Catalogs

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.