- Hydraulics - Pneumatics

- Pump

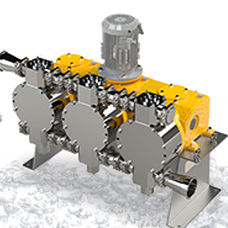

- Slurry pump

- TACMINA CORPORATION

- Products

- Catalogs

- News & Trends

- Exhibitions

Chemical pump slurryhydraulically-operatedsanitary

Add to favorites

Compare this product

Characteristics

- Fluid

- for chemicals, slurry

- Operation

- hydraulically-operated

- Domain

- sanitary

- Applications

- for control, mixing, metering, high-pressure

- Flow

Min.: 0.23 l/min

(0.06076 us gal/min)Max.: 31 l/min

(8.18933 us gal/min)- Pressure

Min.: 8 bar

(116.03 psi)Max.: 25 bar

(362.594 psi)

Description

Features

No Foreign Matter Contamination

Since the pump has no rotating or sliding parts, where foreign matter is normally generated, the risk of contamination is greatly reduced. This pump can be used with confidence in processes that require strict quality control, such as food, pharmaceutical, and electrical machinery manufacturing as well as many other critical applications.

No Reduction of the Flow Rate Even With Pressure Fluctuation.

Integrated backflow prevention means that the flow rate will not be reduced even when the pressure fluctuates. This is ideal for applications that require highly-accurate volume delivery such as mixing and coating pharmaceuticals and those that require accurate mixing ratios.

No Fluid Leakage

No mechanical seal to wear means no risk of leakage.

This is suitable for transferring toxic chemicals that are dangerous if leaked or fluid that is prone to evaporate.

No Break Down When Dry-Running

Thanks to its seal less design the pump does not require the fluid to lubricate the mechanism therefore even if the pump is run dry, it does not affect the drive components. There is no risk of pump break down even when dry-running occurs.

No Deterioration of Fluids

Unlike other products, Smoothflow Pumps never stir or agitates the fluid and they do not apply shear force. There is no risk of fluid deterioration or chemistry change caused by shearing, abrasion, pressure, or temperature change.

Designed for Optimal Slurry Transfer

As the Smoothflow Pump gently pushes the fluid, the wetted parts are not damaged by even the most aggressive slurries such as diatomaceous earth.

Catalogs

No catalogs are available for this product.

See all of TACMINA CORPORATION‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.