- Machine-tools

- Machining Center

- PEEK machining

- Taizhou Ark International Trade Co.,Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

PEEK machining ARKPEEK-Machiningfor electronicsautomotivemedical

Add to favorites

Compare this product

Characteristics

- Treated material

- PEEK

- Applications

- for electronics, automotive, medical, agriculture, industrial, for aeronautics, for the aerospace industry, for the construction industry, chemistry, for robotics, for metal fabrication, for the energy sector, for the food industry, for the plastics industry, for railway, for the maritime sector, optical

- Production method

- medium series, small series, prototyping, large series

- Product applications

- screw, shaft, spacer, for valve bodies, bushings, fitting, fastener, connector, housing, nut, endoscope parts, for valve parts

- Other characteristics

- CNC, precision, high-capacity

Description

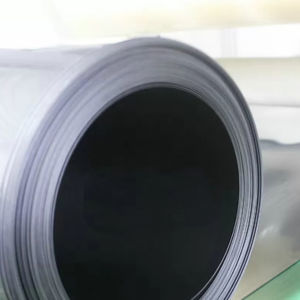

Our Custom Cut PEEK for Machining offers precision-engineered solutions tailored to meet your specific project needs. This high-performance material, Polyetheretherketone (PEEK), is known for its exceptional properties, including thermal stability, mechanical strength, and chemical resistance.

Experience the advantages of custom cut PEEK, which boasts outstanding wear resistance, low friction, and dimensional stability. Elevate your projects with tailor-made PEEK machining solutions, unlocking the full potential of this versatile material to optimize your manufacturing capabilities.

Upgrade your machining efficiency and embrace the possibilities with Custom Cut PEEK for Machining - the solution to elevate your projects to new heights.

Machining PEEK involves the precision shaping and fabrication of Polyether Ether Ketone (PEEK), a high-performance thermoplastic polymer, using CNC (Computer Numerical Control) machining techniques. PEEK's exceptional mechanical properties, chemical resistance, and thermal stability make it a preferred material for various industries.

During machining, CNC machines utilize computer-aided design (CAD) files to precisely cut, mill, turn, drill, and grind PEEK material into desired shapes and dimensions. This process allows for the creation of intricate components with tight tolerances required for critical applications such as seals, bearings, bushings, and structural parts.

VIDEO

Catalogs

No catalogs are available for this product.

See all of Taizhou Ark International Trade Co.,Ltd‘s catalogsOther Taizhou Ark International Trade Co.,Ltd products

PEEK Profiles

Related Searches

- Machining service

- Milling machining

- CNC milling machining

- Precision milling machining

- Automotive milling machining

- Industrial milling machining

- Small series milling machining

- Prototyping milling machining

- Medical milling machining

- Medium series milling machining

- Plastic milling machining

- Aeronautic milling machining

- Machining for the aerospace industry

- Large series milling machining

- Electronic milling machining

- Robotic milling machining

- Agriculture milling machining

- Milling machining for the food industry

- Milling machining for the energy sector

- Auger milling machining

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.