- Products

- Abrasion-resistant PEEK

- Taizhou Ark International Trade Co.,Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Abrasion-resistant PEEK harsh environmentschemical-resistantfor high-temperature applications

Add to favorites

Compare this product

Characteristics

- Protection level

- harsh environments, abrasion-resistant

- Other characteristics

- chemical-resistant, for high-temperature applications

Description

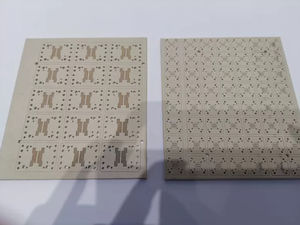

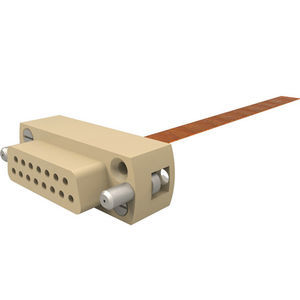

Custom PEEK machined parts are crafted to meet the unique demands of industries requiring high-precision and high-performance materials. PEEK's excellent properties, including its resistance to chemicals, high temperatures, and mechanical stress, make it a versatile material for complex applications. Whether used in semiconductor manufacturing, oil and gas exploration, or medical implants, PEEK components deliver reliable performance under extreme conditions.

PEEK (Polyether Ether Ketone) machined components are premium solutions designed for applications that demand superior performance and durability. As a high-performance engineering thermoplastic, PEEK stands out for its unique combination of properties, making it an ideal choice for critical applications across various industries, including aerospace, medical, oil and gas, and semiconductor manufacturing.

Key Features and Benefits:

PEEK machined components offer outstanding chemical resistance, making them suitable for use in environments exposed to aggressive chemicals and solvents. The material's exceptional thermal stability allows it to maintain its mechanical properties at elevated temperatures, with a continuous service temperature of up to 250°C (482°F) and short-term exposure capability up to 300°C (572°F). This makes PEEK ideal for high-temperature applications, such as in automotive engines and industrial equipment.

In addition to its thermal properties, PEEK exhibits excellent mechanical strength and stiffness, providing high load-bearing capacity and wear resistance.

Catalogs

No catalogs are available for this product.

See all of Taizhou Ark International Trade Co.,Ltd‘s catalogsOther Taizhou Ark International Trade Co.,Ltd products

PEEK Parts

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.