- Products

- Abrasion-resistant PEEK

- Taizhou Ark International Trade Co.,Ltd

- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

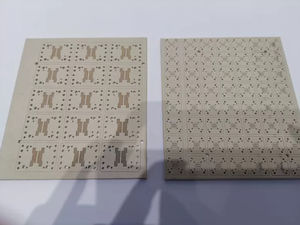

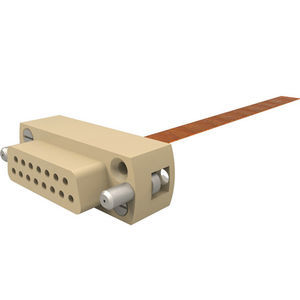

Ribbon PEEK abrasion-resistantanti-corrosionchemical-resistant

Add to favorites

Compare this product

Characteristics

- Shape

- ribbon

- Protection level

- abrasion-resistant, anti-corrosion

- Other characteristics

- chemical-resistant, for high-temperature applications

Description

Enhance the durability and performance of your compressors with our high-performance PEEK parts. Known for their superior mechanical strength and chemical resistance, these parts withstand extreme heat and aggressive substances, making them perfect for use in harsh operating conditions. PEEK compressor parts not only improve operational efficiency but also help reduce wear and tear, resulting in fewer replacements and lower overall costs. Invest in PEEK compressor components for a dependable and cost-effective solution in high-demand applications.

PEEK (Polyether Ether Ketone) compressor parts offer unparalleled performance for industrial applications that require exceptional durability, efficiency, and chemical resistance. PEEK’s unique properties make it an ideal material for manufacturing compressor components that must endure high temperatures, aggressive chemicals, and intense mechanical stress over prolonged periods.

One of the standout benefits of using PEEK for compressor parts is its high-temperature stability. Capable of withstanding temperatures up to 250°C without degrading, PEEK parts maintain their strength and integrity even in extreme heat conditions, which is crucial for maintaining compressor efficiency in high-demand environments. This high heat tolerance also reduces the risk of component failure, extending the lifespan of compressors and minimizing costly downtime.

In addition to its thermal resistance, PEEK’s remarkable chemical resistance makes it suitable for compressors operating in environments exposed to corrosive or abrasive chemicals.

Catalogs

No catalogs are available for this product.

See all of Taizhou Ark International Trade Co.,Ltd‘s catalogsOther Taizhou Ark International Trade Co.,Ltd products

PEEK Parts

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.