- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

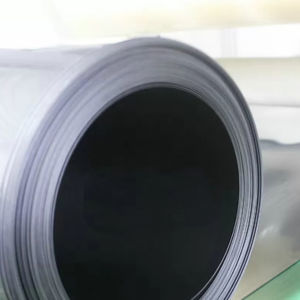

Rod PEEK sheettubularharsh environments

Add to favorites

Compare this product

Characteristics

- Shape

- sheet, rod, tubular

- Protection level

- harsh environments

- Other characteristics

- chemical-resistant, for high-temperature applications, low-friction

Description

Polyether Ether Ketone (PEEK) is a high-performance engineering thermoplastic known for its exceptional strength, chemical resistance, and thermal stability. PEEK plastic is widely used in demanding applications across aerospace, automotive, and medical industries due to its ability to withstand high temperatures and harsh chemical environments. It offers excellent wear resistance and low friction, making it ideal for precision components such as gears, bearings, and seals. Additionally, its biocompatibility makes it suitable for medical implants and devices.

PEEK (Polyether Ether Ketone) is a high-performance plastic with remarkable mechanical and chemical properties. It can endure extreme conditions, including high temperatures and aggressive chemicals, making it ideal for use in critical applications in the aerospace, automotive, and electronics sectors. PEEK plastic provides superior wear and abrasion resistance, ensuring longevity and reliability in components like bushings, valve seats, and pump gears. Its excellent mechanical properties and biocompatibility also allow for its use in advanced medical applications, including surgical instruments and implants.

ARKPEEK-1000: 100%PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fiber reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity.

Catalogs

No catalogs are available for this product.

See all of Taizhou Ark International Trade Co.,Ltd‘s catalogsOther Taizhou Ark International Trade Co.,Ltd products

PEEK Profiles

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.