- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

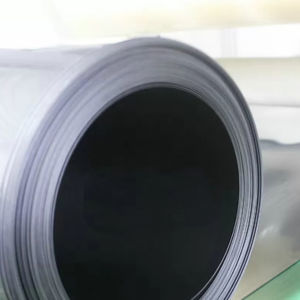

Rod PEEK Virgin sheetchemical-resistant

Add to favorites

Compare this product

Characteristics

- Shape

- sheet, rod

- Other characteristics

- chemical-resistant

- Length

1,000 mm

(39.37 in)- Width

Max.: 700 mm

(27.56 in)Min.: 6 mm

(0.24 in)- Thickness

Max.: 800 mm

(31.496 in)Min.: 0.5 mm

(0.02 in)

Description

Virgin PEEK, a high-performance polymer of pristine quality, boasts remarkable attributes such as exceptional chemical resistance and thermal stability. Discover its applications across industries where reliability and strength are paramount. Explore the unique advantages of virgin PEEK for your diverse industrial needs.

Virgin PEEK refers to Polyether Ether Ketone (PEEK) in its pure, unaltered form, without any additives or fillers. This high-performance thermoplastic exhibits exceptional mechanical properties, chemical resistance, and thermal stability. Widely utilized in industries such as aerospace, automotive, and medical, Virgin PEEK offers outstanding dimensional stability and strength. It is commonly used for critical applications such as bearings, bushings, seals, and structural components where reliability and performance under extreme conditions are paramount. Virgin PEEK stands as a reliable and versatile material, ensuring durability and precision in various engineering applications.

ARKPEEK-1000: 100% PEEK

Produced from virgin polyetheretherketone resin and offers the highest toughness and impact resistance of all types.

ARKPEEK-CF30: 30% Carbon Fiber + 70% PEEK

Carbon fibre reinforcement lends the material a high level of rigidity and creep strength, high mechanical strength and heat conductivity values.

ARKPEEK-GF30: 30% Glass Fiber + 70% PEEK

Glass filled PEEK exhibits increased mechanical strength and high rigidity. Improved creep strength and dimensional stability are achieved by this glass filled PEEK. These properties make this material suitable for use in parts which are exposed to high static loads over long periods in high temperature conditions.

Catalogs

ARK PEEK Material Properties

4 Pages

ARKPEEK Product Catalogue

8 Pages

Other Taizhou Ark International Trade Co.,Ltd products

PEEK Profiles

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.