- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

Round belt polyurethanefor light-duty applicationsfor food

Add to favorites

Compare this product

Characteristics

- Type

- round

- Material

- polyurethane

- Product applications

- for food, for conveyor rollers, for machine tools, for machines, strip, for food industry machinery, for food, handling, for packaging machines, for automation, for light-duty applications, for medical devices, for bottles, for packaging

- Sector

- industrial, for the textile industry, for the food industry, for the automotive industry, for the packaging industry

- Other characteristics

- friction, anti-static, elastic, custom, anti-static, metric, Kevlar®, sturdy, connectable, hollow, twisted

Description

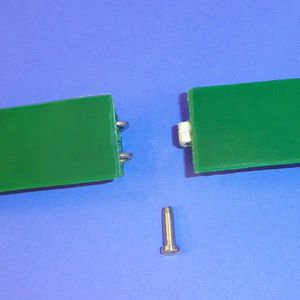

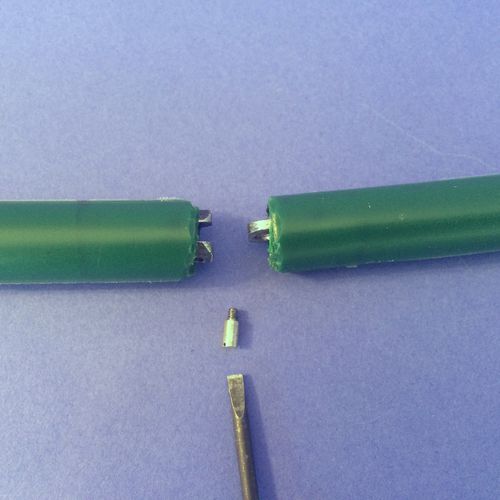

Mechanical assemblies ERO Joint® for round belt are available in Polyurethane and Polyester from 8mm diameter.

The assembly is made by a longitudinal screwing in two stainless steel pieces embedded in the material of the belt. Other types of mechanical connection are possible and currently improved.

Polyurethane round belts ERO Joint® are suitable for power transmission or for transport.

In all cases, the mechanical assemblies ERO Joint® are linked to a traction cord embedded in the belt in order to provide the required mechanical resistance. (ERO Joint® is also available in belts without traction cord).

In such cases, a traction element is added to assure the mechanical resistance of the mechanical joint.

ADVANTAGES

Advantages are a fast and easy installation and assembly.

With this new solution of mechanical joint system, you will save time and optimize your production downtime by reducing the repair time.

The mechanical assembly of ERO Joint® round belts is substantially better compared to another mechanical joint system.

There is no other mechanical joint system in round belts with traction cord.

Mechanical fastening systems ERO Joint® are lasting solutions.

The ERO Joint® round belts are spliced in our production using a patented process and fitted with the length requested.

Anyway using ERO Joint® round belts ensure you a complete freedom and a high-flexibility: no specific tool, no splicing and welding procedure to respect, no deburring, no risk to miss the welding. ERO Joint® round belts are easy to assemble.

Alternatives

Hollow round belt with fastening system

Hollow round belt with connector are only used for very low mechanical resistance.

VIDEO

Catalogs

No catalogs are available for this product.

See all of TANALS_ERO Joint®‘s catalogsRelated Searches

- Power transmission belt

- Industrial power transmission belt

- Rubber power transmission belt

- Plastic strip

- Timing belt

- Sturdy belt

- PU belt

- V belt

- Synchronous power transmission belt

- Flat strip

- Oil-resistant power transmission belt

- Flexible belt

- High-performance power transmission belt

- High-resistance power transmission belt

- Trapezoidal power transmission belt

- Pulley power transmission belt

- Abrasion-resistant strip

- Heat-resistant power transmission belt

- Endless power transmission belt

- Belt for the textile industry

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.