- Products

- Automatic laminator

- Tangshan Jiasun Import and Export Co.,Ltd

- Products

- Catalogs

- News & Trends

- Exhibitions

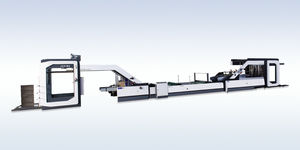

Automatic laminator QTM1 series

Add to favorites

Compare this product

Characteristics

- Options

- automatic

Description

QTM1300/1450/1650 High-speed Automatic Flute Laminator

II. Features of the machine:

a) Key Points

i. High Speed: It can run 11000 sheets per hours for sheet length 450mm.

ii. High Precision: At normal speed the precision can be controlled at ±1 mm with the yield 98%.

iii. Glue saving: It can be 16 grams of glue per square meter.

b) General Introduction:

The QTM series High Speed Automatic Flute Laminator is suitable for the lamination of printed cardboard paper with 3 ply or 5 ply corrugated sheet which is mainly used in food, beverage boxes etc.

The machine adopts chasing registration method with the help of imported low-voltage parts, liquid sensor and motion control system.

c) Machine Structure:

Upper Feeding Part:Feed the paper of 120-450gsm. It can be thinner according to the size and quality of the paper

Bottom Feeding Part:Feed different kinds of corrugated sheet between ABCEF 3&5 Ply.

Conveyor:Press the laminated paper and convey to the paper delivery unit.

Gluing Part:Coating glue on the bottom paper.

d) Features by Parts:

i. Upper Feeding Part:

1. High speed feeder with 3 sucking suckers and 4 delivery suckers with the highest speed 12000 sheets per hour.

2. Double sucking rubber and single rubber forwarding which can avoid effectively double paper.

3. There are two side blowers as well. The position of the side blower can be adjusted to ensure the smooth feeding of paper.

ii. Top Paper Conveying Part:

The conveying of the face paper unit adopts scale feeding method,

Other Tangshan Jiasun Import and Export Co.,Ltd products

Lamination and Patching

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.