EVERYTHING YOU NEED

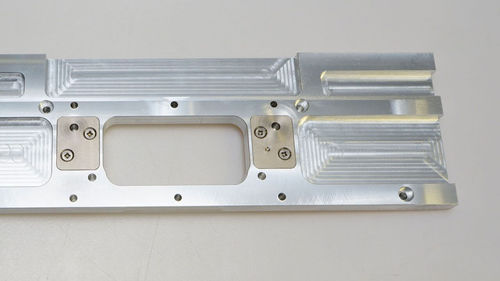

Tannlin specialise in the design and manufacture of support products - dedicated Tooling and Fixturing for the PCB assembly processes.

PRINT, PLACE & REFLOW

Print support plates along with process carriers are used to ensure the best print and optimal processing during manufacture of a PCB assembly.

Benefits of Print Support Plates include:

• Ensures optimal gasket of printed circuit board to stencil during the print process, (significant contribution to First Pass Yield).

• SMT components are fully protected during second side printing.

• Fast set-up and product changeover.

Process (Print, Place and Reflow) Carriers allow processing of all sizes and configurations of printed circuit boards.

Benefits of process carriers include:

• Retention of printed circuit boards that are not compatible with standard conveyor systems.

• Fiducial alignment to the carrier.

• Processing of small form factor, flexi and hybrid printed circuit boards.

SMT SUPPORT PRODUCTS

Working with 3D CAD modelling and integrated CAM we create and simulate bespoke design solutions to drive our suite of machining centres. Our focus is aimed at design solutions that increase the process operating window and deliver a direct benefit to process yield.

Materials

• High Temperature glass composites.

• Aluminium (K100s cast tooling plate or equivalent).

• Stainless Steel.

• Titanium.

Surface treatment

• Teflon Coating.