Plasma surface treatment machine RotoVAC

Add to favorites

Compare this product

Characteristics

- Type

- plasma

Description

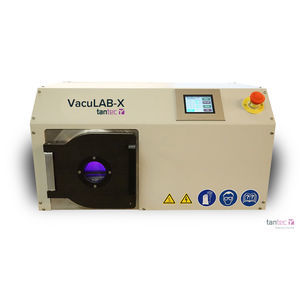

Tantec RotoVAC vacuum plasma treater is designed for plasma treatment of small injection moulded plastic parts, without the need to place them in a jig or use complicated handling systems.

With the RotoVAC drum design, simply fill the drum and place it in the vacuum chamber. The rotation will ensure that all parts are treated.

In the treating chamber a vacuum builds up to between 1 and 4 mbar before an electrical discharge is created through the integrated plasma electrode. Treatment cycle times are often short, between 20-180 seconds depending on the material and its formulation.

The RotoVAC plasma treater is appreciated for its simplicity of operation, reliability in production and fast process speed. Treating gasses such as argon and oxygen can be applied, but in most cases this is not necessary due to the high power exposed by the plasma discharge. RotoVAC uses the advanced Tantec power generator HV-X series as power supply, and specially designed plasma transformers to provide voltage to the plasma electrodes.

The rotating drum ensures that all parts are equally treated. The concept includes an extra drum which can be loaded during treatment and simply exchanged with the one in use when the batch is completed.

VIDEO

Catalogs

Related Searches

- Generator

- Surface treatment machine

- Plasma surface treatment machine

- Automatic surface treatment machine

- Laboratory surface treatment machine

- Corona effect surface treatment machine

- 3D part surface treatment machine

- Medical device surface treatment machine

- Vacuum surface treatment machine

- Plate surface treatment machine

- Discharge generator

- Surface treatment generator

- Atmospheric surface treatment machine

- Stand-alone generator

- Sheet surface treatment machine

- Corona discharge generator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.