Plasma surface treatment machine VacuTEC 5050vacuum

Add to favorites

Compare this product

Characteristics

- Type

- plasma

- Other characteristics

- vacuum

Description

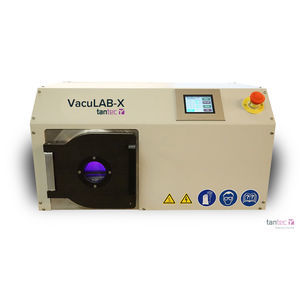

Tantec’s VacuTEC 5050 Plasma Treater is designed for the treatment of a large number of different injection molded parts.

The VacuTEC offers very fast treatment times and optimum adhesion properties for downstream coating, gluing, painting, and printing applications.

In the treating chamber, a vacuum is built up to between 0,1 and 3 mbar before an electrical discharge is created through the integrated plasma electrode.

Treatment cycle times are often short, between 5 – 600 seconds depending on the material and its formulation.

Effective size for products on 2 shelves: 500 x 500 x 100 mm. The VacuTEC is appreciated for its simplicity of operation, reliability in production, and fast process speed.

Easy to install and use Connect to mains power.

Fast treatment times High power impact enables treatment times from 5 – 600 seconds, depending on the material.

Vacuum level The plasma discharge is active from 0,1 – 3 mbar depending on the application.

Process gas Process gasses such as oxygen and argon can be used, but in most cases, it is not necessary.

Process control The entire plasma process is controlled by the HV-X generator and the PLC unit. All parameters are displayed through the touch panel.

Cost-efficient surface treatment Due to the low power consumption and no need for special treatment gasses the unit is a very cost-efficient solution for improving surface wettability and adhesion.

Vacuum pressure Plasma Enables treatment of both conductive and non-conductive surfaces.

Chamber door Hinged door with window and safety switch.

Mains voltage and frequency 100-480 VAC 50/60 Hz

Output voltage/plasma power 5kV / 1000W

Power source HV-X10 Generator

VIDEO

Catalogs

No catalogs are available for this product.

See all of Tantec‘s catalogsRelated Searches

- Generator

- Surface treatment machine

- Plasma surface treatment machine

- Automatic surface treatment machine

- Laboratory surface treatment machine

- Corona effect surface treatment machine

- 3D part surface treatment machine

- Medical device surface treatment machine

- Vacuum surface treatment machine

- Plate surface treatment machine

- Discharge generator

- Surface treatment generator

- Atmospheric surface treatment machine

- Stand-alone generator

- Sheet surface treatment machine

- Corona discharge generator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.