Ozone surface treatment machine OzoneTECautomatic

Add to favorites

Compare this product

Characteristics

- Type

- ozone

- Other characteristics

- automatic

Description

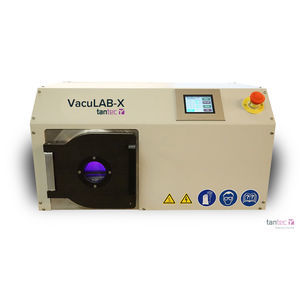

Tantec has developed its OzoneTEC System to treat the inside of products such as surfboards, coolers, ice boxes, jacket pipes, small boats, etc. – products that consist of fiberglass on the outside and foam on the inside – also called sandwich construction.

The OzoneTEC produces ozone, which is blown into the shell and is left inside for a while before it is sucked out again. Thereafter the Polyurethane Foam is injected. It then hardens and adheres to the inside of the shell.

Features:

Ability to treat the interior of rotomolded parts

Higher surface energy levels achieved compared to stock resins

On-demand treating

Flexible settings to allow for treatment of various product sizes and dimensions

Small footprint

No exotic treating gases required

VIDEO

Catalogs

No catalogs are available for this product.

See all of Tantec‘s catalogsRelated Searches

- Generator

- Surface treatment machine

- Plasma surface treatment machine

- Automatic surface treatment machine

- Laboratory surface treatment machine

- Corona effect surface treatment machine

- 3D part surface treatment machine

- Medical device surface treatment machine

- Vacuum surface treatment machine

- Plate surface treatment machine

- Discharge generator

- Surface treatment generator

- Atmospheric surface treatment machine

- Stand-alone generator

- Sheet surface treatment machine

- Corona discharge generator

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.