- Company

- Products

- Catalogs

- News & Trends

- Exhibitions

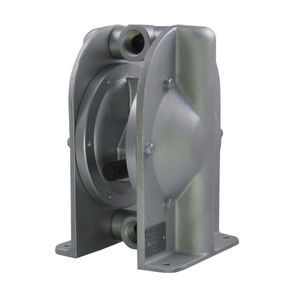

Double-diaphragm pump T800for chemicalsair-drivenindustrial

Add to favorites

Compare this product

Characteristics

- Technology

- double-diaphragm

- Fluid

- for chemicals

- Operation

- air-driven

- Domain

- industrial, chemical

- Material

- PP, polyethylene, PTFE

- Other characteristics

- mechanical

- Flow

Min.: 0 l/min

(0 us gal/min)Max.: 820 l/min

(216.62108 us gal/min)- Pressure

8 bar

(116.03 psi)

Description

Type: - T 800

Atex/FDA: - TX 800 (ATEX)

Material: - PE or PTFE

m3/h; l/min: - a max capacity of 820 l/min.

Spheres to use: -

• - Chemistry: acids, alkalis, alcohol, solvents, latex, emulsions

• - Food: CIP fluid, flavouring, pigments

• - Pulp, Paper: glue, slurries, adhesives, dispersions, resins, sodium silicate, titanium oxide

• - Surface conditioning: electroplating baths, various acids, solvents, anodic sludge, varnish, enamels

• - Water treatment: sludge handling, filter press applications, neutralization and flocculants

• - Electronics: carrier fluids, ultra pure liquids, electroplating solutions, mercury, solvents

• - Modular design concept

• - Print, paint: glue, additives, varnish, ink, paint, latex, acid, resins, pigment

Possible sizes: - TR 9, TR20, T50, T100, T200, T400, T800

Temperature max: - +110 C

Pressure: - 8 bar

Description: - Polyethylene pumps

Polyethylene (PE HD) has a superior wear resistance

which is 6 – 7 times better than for polypropylene

(PP). This fact makes the pump suitable for handling

abrasive slurries etc. PE is resistant to most kind of

aggressive chemicals such as concentrated acids

and alkalis.

Tapflo uses different grades of PE depending on the

part. For valve seats and ball stoppers, which are most

vulnerable to wear - UHMW PE1000 is used for best

mechanical strength and abrasion resistance.

PTFE pumps

PTFE (virgin polytetrafluorethylene) is a thermoplastic

polymer with superior chemical resistance. The PTFE

pump can handle even the most aggressive acids.

T800 and is our largest pump

Motor, kW - No motor in construction

Dimensions: - 460 × 589 × 830 mm

Catalogs

AIR OPERATED DIAPHRAGM PUMPS

40 Pages

Related Searches

- Pump

- Industrial pump

- Pump with electric motor

- Stationary pump

- Clear water pump

- Centrifugal pump

- Self-priming pump

- Chemical pump

- Stainless steel pump

- Lubricant pump

- Transfer pump

- Chemistry pump

- Suction pump

- Compact pump

- Lubricating oil pump

- Diaphragm pump

- Submersible pump

- Air-driven pump

- Flow pump

- Mechanically-actuated pump

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.