Threaded insert Suresert®metalroundfor plastics

Add to favorites

Compare this product

Characteristics

- Type

- threaded

- Material

- metal

- Configuration

- round

- Applications

- for plastics

Description

Brass threaded insert for stress-prone plastics

The Tappex Suresert® is designed for Ultrasonic or Heat installation into notch sensitive thermoplastics.

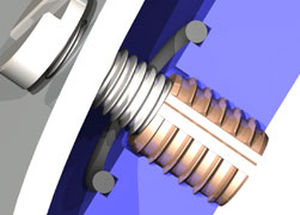

The double-ended design, see image, includes two annular bands of knurling with a curved form rather than the more conventional pyramid form, central undercut, and pilots at either end.

Notch sensitive thermoplastics tend to be affected by the form on the insert surface, particularly by sharp edges and corners which act as stress raisers

Suresert threaded inserts for stress-prone plastics

can initiate cracking. The Suresert design utilises a curved knurl form to reduce the formation of stress raisers in the body of the plastic. In application the torque applied through the fastener is transmitted by the curved knurl form into the plastic in a more progressive manner.

The Suresert insert is double ended simplifying orientation before installation into the plastic moulding for manual and automatic assembly methods.

Suresert® Advantages:

Reduced in place stress over conventional barbed inserts.

Particularly suitable in stress prone thermoplastic materials.

Heat or ultrasonic installation.

Double ended to simplify automatic and manual installation.

Pilots provide a means of alignment with the receiving hole.

The part number is defined 202, followed by the thread size. Available in sizes M3 and M4, other sizes available to customer order.

Catalogs

Related Searches

- Screw

- Steel screw

- Threaded insert

- Metal insert

- Round insert

- Bind-head screw

- Stainless steel screw

- Nickel-plated brass insert

- Stainless steel insert

- Phillips screw

- Steel insert

- Plastic insert

- Self-tapping screw

- Press-in insert

- Self-tapping insert

- Molded-in insert

- Flat insert

- Plastic insert

- Ultrasonic installation insert

- Plastic screw

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.