Automated filling station TAVA series drumfor liquidsfor pasty products

Add to favorites

Compare this product

Characteristics

- Operational mode

- automated

- Container type

- drum

- Product applications

- for pasty products, for liquids

- Domain

- industrial

- Type

- vacuum

- Other characteristics

- fill-to-level

- Volume

200 l

(52.8 gal)

Description

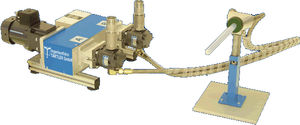

In the production of adhesives and sealants, high-viscosity pastes are packaged in clamping ring lid drums. These cylindrical containers are fed into various dosing and/or mixing systems for processing the pasty plastics. The problem: If air chambers have formed in the material during manufacturer-side filling, this “disturbing air” enters the system during the removal and dosing process. This can affect the processing so much that it is necessary to stop the process and the complete system must be “flushed” with material until all disturbing air is removed. This not only results in loss of material; often components also have to be replaced, leading to downtimes and the production of environmentally harmful waste.

The vacuum filling station TAVA F is suitable for drum filling at the material manufacturer as well as for material preparation before the processing at the user himself.

The vacuum loading of the drum and the almost simultaneous filling is fully automated. A drum is filled in a few minutes – free of air inclusions and humidity/air moisture. In addition, storage stability is improved, as no contamination by (air) moisture can take place.

BASIC EQUIPMENT

• Sight glass

• Different tube lengths

• Requires compressed air

• Power connection: 400 volts

VIDEO

Catalogs

No catalogs are available for this product.

See all of TARTLER GmbH‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.