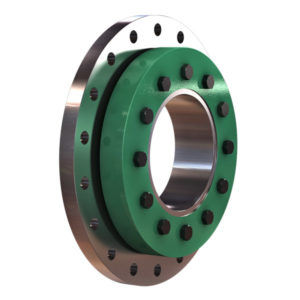

Shrink disc 3393 series

Add to favorites

Compare this product

Characteristics

- Torque

Max.: 14,730,000 Nm

(10,864,290.4589 ft.lb)Min.: 970 Nm

(715.4353 ft.lb)

Description

The main function of a shrink disc is the safe connection of a shaft to a hub by means of frictional locking. For example between a drive shaft and a hollow gear shaft. The shrink disc creates a backlash-free connection by pressing the hub onto the shaft. This type of connection is mainly used for torque transmission.

The shrink disc only provides the required forces and does not itself transmit any forces or torques between shaft and hub.

It is therefore not in the force flow. Assembly is carried out by pushing the shrink disc onto the hollow shaft and then tightening the screws. By using conical surfaces, the inner diameter is reduced and the radial pressure is built up. Series 33xx shrink discs are self-locking. The clamping forces are therefore provided by the screws.

These are tightened flush (path controlled). The shrink discs are supplied ready for installation. For a perfect function and to achieve a sufficiently high coefficient of friction, the contact surfaces between shaft and hub must be free of grease, dry and clean. The functional surfaces of the shrink disk, threads and head supports of the screws are already lubricated ex works. Molykote G-Rapid Plus or a comparable lubricant should be used. The contact surfaces between the sleeve and hub should be oiled or greased before assembly.

Catalogs

No catalogs are available for this product.

See all of TAS-Schäfer GmbH‘s catalogs*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.