- Products

- Catalogs

- News & Trends

- Exhibitions

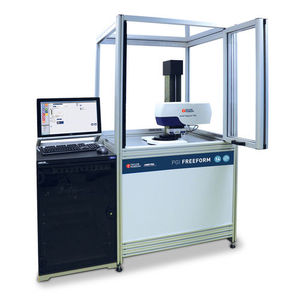

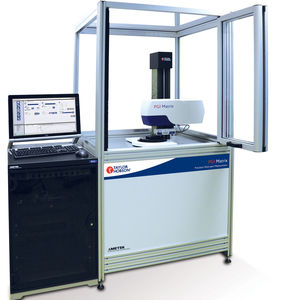

Stylus surface measuring system Talysurf® PGI Opticsopticalindustrial

Add to favorites

Compare this product

Characteristics

- Technology

- stylus, optical

- Domain

- industrial

Description

Optics Surface Finish & Form Measurement Equipment

The Form Talysurf® PGI Optics contact stylus optical profilometer, measures surface finish & form of Optical components, from a large diameter lens with large SAG to small low SAG plastic lenses.

Producing high accuracy measurements on spherical, diffractive, fresnel and aspheric lenses up to 300 mm diameter (single trace) as well as more complex surfaces such as cylinders and freeforms. The system is also capable of measuring both IR (infra red), visible substrates and mirror optics.

These capabilities make the Form Talysurf® PGI Optics the goto instrument for optical manufacturers.

A fast, high accuracy measurement system for precision optics.

Following its first release in 1984, the Form Talysurf® quickly became the number one choice for optics manufacturers measuring aspheric form error. Since then, we have installed thousands across the world, making the Form Talysurf® PGI a true industry standard.

Our patented PGI (Phase Grating Interferometer) technology enables you to measure large sags with short length styli for the highest accuracy measurements. These Taylor Hobson manufactured styli combine very high stiffness and low force, which delivers much greater accuracy and repeatability than comparable products.

A benchmark for accuracy and versatility

•Easy to program, fast and accurate

•Designed for production environments

•Powerful analysis tools to improve your capacity and capability

•Time-saving software functions - One-click measurements

•Measurement of large sag lenses without compromise

•Automated software routines for repeatable high accuracy measurements

Catalogs

No catalogs are available for this product.

See all of TAYLOR HOBSON‘s catalogsRelated Searches

- Measuring device

- Measuring machine

- Optical measuring machine

- Automatic measuring machine

- High-precision measuring machine

- Measuring system for industrial applications

- Parts measuring machine

- Benchtop measuring device

- Distance measuring machine

- Control measuring machine

- Geometry measuring device

- Surface measuring machine

- Compact measuring machine

- Industrial profiler

- CNC measuring machine

- High-speed measuring machine

- Contour measuring machine

- Angle measuring machine

- Shape measuring machine

- Roughness tester

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.