- Products

- Catalogs

- News & Trends

- Exhibitions

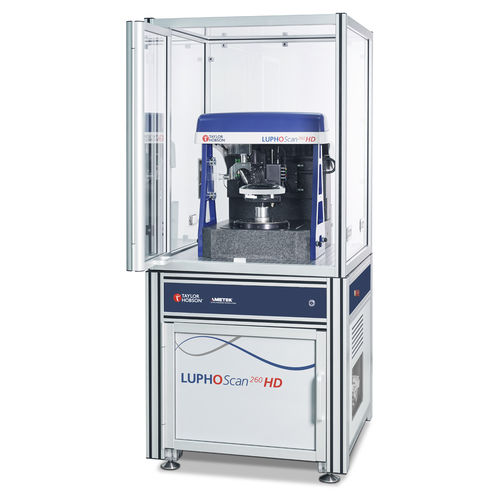

Non-contact profilometer LUPHOScan 260/420 HDoptical3Dsurface flatness

Add to favorites

Compare this product

Characteristics

- Technology

- optical, 3D

- Function

- surface flatness, shape measurement

- Domain

- industrial

- Other characteristics

- non-contact

Description

Non-contact 3D Form/Shape Measurement Equipment for Aspheric, Freeform Optics & Lens Mold Measurement

The LUPHOScan HD non-contact 3D optical profilometer/equipment delivers the highest accuracy for radius and irregularity on challenging surfaces such as high departure aspheres and freeforms. The industry-leading stability guarantees accuracy even in the most challenging environments and provides fast measurement cycle times with no loss in accuracy. The next generation 3D profilometer/equipment provides an industry first with instrument accuracy better than ±50 nm (3σ) on sample slopes up to 90°.

The LUPHOScan HD platforms are interferometric, scanning metrology systems based on MWLI® technology (multi-wavelength interferometry).

They are designed to perform ultra precision non-contact 3D form measurements of rotationally symmetric surfaces such as aspheric lenses, spheres, flats and freeforms.

Key benefits of the LUPHOScan HD include fast measurement speeds, high flexibility with regard to uncommon surface shapes (e.g. flat apexes or profiles with points of inflection), and maximum object diameters up to 420 mm.

Revolutionary measurement and analysis capability

•Analysis of any rotationally symmetric surface - Aspheres, spheres, flats and freeforms

•Highest accuracy on object slopes up to 90° - Ideal for measuring strong, steep, and small aspheres including cell phone lens moulds

•Measurement of almost any material - Transparent, specular, opaque, polished, ground

•Large spherical departures - Measure pancake or gullwing surfaces and profiles with points of inflection

Catalogs

LuphoScan 260/420HD

3 Pages

Related Searches

- Measuring device

- Measuring machine

- Optical measuring machine

- Automatic measuring machine

- High-precision measuring machine

- Measuring system for industrial applications

- Parts measuring machine

- Benchtop measuring device

- Distance measuring machine

- Control measuring machine

- Geometry measuring device

- Surface measuring machine

- Compact measuring machine

- Industrial profiler

- CNC measuring machine

- High-speed measuring machine

- Contour measuring machine

- Angle measuring machine

- Shape measuring machine

- Roughness tester

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.