CAM software for multi-function milling-turning machines

Add to favorites

Compare this product

Characteristics

- Function

- CAM

- Applications

- for multi-function milling-turning machines

Description

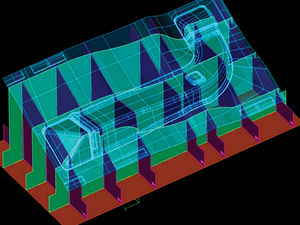

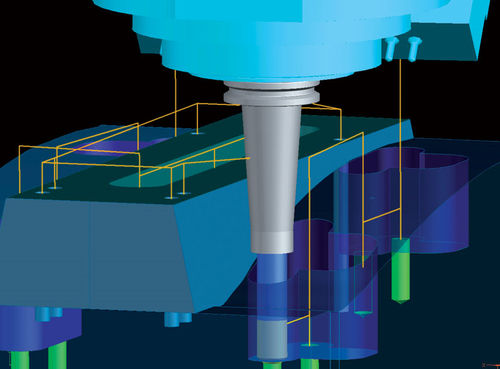

Typical application areas for this Tebis CAM module in die manufacturing include planar surfaces, seating surfaces, and fit and tapped holes for attaching trim steels to sheet metal dies. Mold manufacturers use the module for machining all kinds of pocket and planar surfaces as well as holes, such as step or deep-drilled holes for cooling and heating systems. But industrial and aerospace engineering are also typical application fields.

Use the drilling functions to program NC programs for bore holes, threads and fits. You can use the milling functions to create individual NC programs for pockets and planar surfaces and for vertical contours and their residual stock machining. With the feature technology, the functions will copy over all the geometry information with a single click of the mouse.

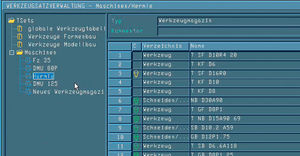

Effective and safe automation

NC set technology provides special advantages for 2.5D NC programming. The system accesses old machining sequences (NC sets) that were defined in the past by milling specialists and have been saved to a central location. The NC sets bundle individual functions for standardized machining steps such as multi-stepped holes, taps and pockets, including all necessary tools and the optimum cutting parameters. If the CAD model contains features (parametric manufacturing objects), NC programming can take place completely automatically because each feature will find the NC set defined for its manufacture. This will result in enormous reductions in NC programming work while increasing safety.

Catalogs

No catalogs are available for this product.

See all of TEBIS‘s catalogsRelated Searches

- Analysis software solution

- Computer-aided design software

- Design software solution

- 3D software solution

- Quality software

- Simulation software

- Programming software

- CAM software

- CAD/CAM software

- Milling software

- CNC machine software

- Finished element analysis software

- Reverse engineering software

- Machining center software

- Surface model software

- Electrode software

- Laser cutting software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.