CAM software for 2 to 5-axis laser cutting

Add to favorites

Compare this product

Characteristics

- Function

- CAM

- Applications

- for 2 to 5-axis laser cutting

Description

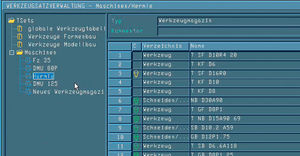

This CAM module is used to generate 2 to 5-axis NC programs offline for laser cutting applications. Using this software, you can trim auto body sheet metal parts for prototypes and series. Die makers use Tebis laser cutting stations to test drawing operations in the try-out phase to find out how to compensate for the springback behavior of the trimmed sheet metal parts.

5-Axis Laser Cutting provides both cutting functions for machining free curves and for generating regular geometric inner contours such as circles and slots. The system automatically monitors the machine’s kinematic properties such as tilting limits or preferred starting position during toolpath calculations. Users can jump in at any time however and manually define the head position and orientation. The system supports users with its comprehensive analysis functions for the rotation angle course, normal deviations and collisions. The Tebis NC jobs administer all change statuses and define mirrored, rotated or moved machining steps.

Semi and fully automatic collision checking

When the NC programs are calculated, the part and trim areas are automatically checked for collisions, taking the entire laser head into account. These collision checks can be extended to clamping elements. Tebis automatically determines where there is a risk of collisions with the component or another element and lets the user remedy the situation graphically and interactively.

Modifications added to the NC program at the machine can be read back into the NC jobs. That lets changes be edited in Tebis.

Catalogs

No catalogs are available for this product.

See all of TEBIS‘s catalogsRelated Searches

- Analysis software solution

- Computer-aided design software

- Design software solution

- 3D software solution

- Quality software

- Simulation software

- Programming software

- CAM software

- CAD/CAM software

- Milling software

- CNC machine software

- Finished element analysis software

- Reverse engineering software

- Machining center software

- Surface model software

- Electrode software

- Laser cutting software

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.