- Industrial machines and equipment

- Heat Exchanger and Refrigeration

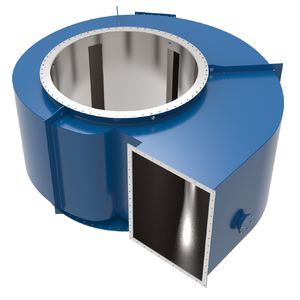

- Nozzle mix burner

- A TEC GRECO Combustion Systems Europe

Nozzle mix burner FLEXIFLAME™heavy fuel oilnatural gasmulti-fuel

Add to favorites

Compare this product

Characteristics

- Type

- nozzle mix

- Power source

- heavy fuel oil, natural gas, multi-fuel, solid fuel

- Firing

- indirectly fired

- Applications

- for rotary kiln

- Other characteristics

- low-NOx

- Power

175,000,000 W

(597,124,500 BTU/h)

Description

FLEXIFLAMETM burners are the most advanced technology developed by GRECO for rotary kilns firing pulverized fuel.

Using three shaping airflows and a unique design - two of the airflows rotate to enfold the solid fuel injection flow - it allows, throgh simple procedures, to optimize complex fuel firing and great control over NOx emissions.

FLEXIFLAMETMburners are developed to meet, with flexibility and without any efficiency loss, the specific necessities of rotary calciner kilns used to make white and grey clinker, lime and pozzolana, among others products.

FLEXIFLAMETM burners are customized to deliver thermal power up to 175 MW. They can use just one or multiple fuels, with variable mix, as:

* Solid fuels: petcoke, anthracite, lignite, bituminous coal, charcoal, etc.

* Liquid fuels: ligh and heavy fuel oil, diesel oil, vegetable oils, etc.

* Gas fuels: natural gas, lean gas, etc.

* Liquid waste: solvents, paint waste, water from cleaning oil products tanks, sewage sludge, etc.

With four independent air channels, FLEXIFLAME™ burners deliver a flame with the best shape and settings for the production process, feedstock and fuel mix. Through simple procedures as opening (or closing) inlet air valves, kiln operators can optimize firing conditions in a way that is not possible for burners that do not count on FLEXIFLAME™ features.

The FLEXIFLAME™ burner versatility and features - that includes the capability to be operated locally or via remote control - make it the best option for applications where NOx emissions control are mandatory or when the firing includes complex fuels, including alternative fuels like plastic fluff.

Catalogs

Other A TEC GRECO Combustion Systems Europe products

Products

Related Searches

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.