- Materials - Tools - Components

- Semi-finished products

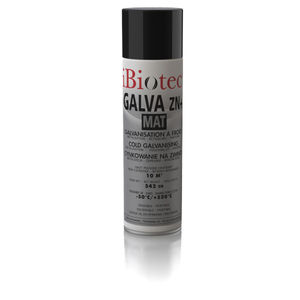

- Corrosion protection spray

- TEC INDUSTRIES SERVICE

Corrosion protection spray Galva ZN+ Ultra Glossycold galvanizermulti-usenon-flammable

Add to favorites

Compare this product

Characteristics

- Function

- corrosion protection, cold galvanizer

- Applications

- multi-use

- Other characteristics

- non-flammable

- Size

522 ml

(17.65 US fl oz)

Description

The literature on cold-galvanising products is extremely dense. Manufacturers and distributors alike release documentation that is, more often than not, sales-oriented. For economic reasons, the vast majority of these aerosols are packaged using liquefied butane or propane gas. Aside from the hazards of these extremely flammable and explosive gases, with a flash point of -58°C, the concentration of the active galvanising ingredient is very low, at around 20-30%. This results in a low cost price and, accordingly, a low retail price. However, only a small surface area can be treated. The real cost is far from clear. Manufacturers rarely commit on this score, with the more reputable stating coverage of 1.2 m² to 1.8 m². Weighing the aerosol before use is very revealing. The primary function of a cold-galvanising product is to protect against corrosion. There is a standardised method to test the performance of a protective anti-corrosion, as set out in the ISO 9227 and ISO 4623-3 standards. Few manufacturers guarantee the performance of their products, considering that in the majority of cases, users require galvanising products for touch-up work; this is known by professionals as "make-up". Nor do they back up these results through test reports carried out by certified laboratories.

We subscribe to different values.

Temperature resistance : +550°C.

Dust dry after 4'30 minutes, touch dry after 7 minutes.

Catalogs

No catalogs are available for this product.

See all of TEC INDUSTRIES SERVICE‘s catalogsRelated Searches

- Metal aerosol spray

- Protective spray

- Hard cleaning job detergent

- Cleaning cleaning product

- Plastic spray

- Lubricant spray

- Anti-corrosion spray

- Multi-use aerosol spray

- Lubricant paste

- Flammable spray

- High-temperature paste

- Metal cleaning product

- Degreasing spray

- Metal paste

- Solvent spray

- Glass spray

- Assembly paste

- Duster spray

- Stripper

- Detergent-degreaser

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.