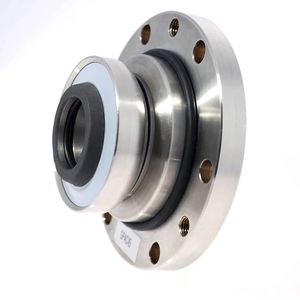

Metal seal HELICOFLEX®spring-loadedindustrialfor chemical applications

Add to favorites

Compare this product

Characteristics

- Type

- spring-loaded

- Material

- metal

- Application

- industrial, for chemical applications, for pump, for aerospace applications, for automotive applications, for the petroleum industry, flange, compression, for storage tanks, for specific applications, for the pharmaceutical industry, for medical equipment, for aircraft, flange, for corrosive products, for medical applications, for fuel cells, for compressors, for valves, for high-temperature applications, for the petrochemical industry, for chemicals, for submarines, vacuum, rugged, for hazardous areas, engine

- Fluid

- for gas

- Other characteristics

- high-pressure, static, radial, high-temperature, chemical-resistant, spring, flexible, custom-made, abrasion-resistant, custom, large, large-diameter

- Temperature limit

Min.: -272 °C

(-458 °F)Max.: 800 °C

(1,472 °F)- Pressure limit

Max.: 3,000 Pa

(0.4 psi)- Diameter

Min.: 4 mm

(0.157 in)Max.: 8,000 mm

(314.961 in)

Description

The HELICOFLEX® seal is a high performance, flexible metal seal that has exceptional compression and elastic recovery properties. This seal is composed of a close wound helical spring surrounded by one or more metal jackets. The spring is designed to have a specific compression resistance. During compression, the resulting specific pressure forces the jacket to yield and fill the flange imperfections while ensuring positive contact with the flange sealing faces. Each coil of the helical spring acts independently and allows the seal to conform to surface irregularities on the flange surface.

HELICOFLEX® design flexibility allows Technetics engineers to customize the seal characteristics to match each unique application.

Features & Benefits

- Highest sealing level performance on the market, depending on the sealing load, the surface finish, and the surface treatment

- Excellent corrosion resistance

- Wide range of materials: from standard to specific and/or rare

- Special materials on demand for coatings: wide range of materials available, from standard to specific and/or rare (see details below in “Specifications” section)

- Extended lifetime and more

- Excellent radiation resistance

- Compatible with NACE MR 0175

- Ø 4 to 8000 mm

- Ø 1,5 to 40 mm cross-section

- Adaptable to all types of sealing surfaces (triple faces, radial, shaped, and more)

- Adaptable to all standards flanges (PNEUROP, ANSI, ISO, and more)

Product Applications

- Nuclear: reactor pressure vessels, control rods, primary pumps, pressurizers, spent fuel casks, transportation casks

- Valves: body/bonnet sealing, seat sealing

VIDEO

Catalogs

HELICOFLEX®

20 Pages

Quick Disconnect Systems (QDS)

12 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.