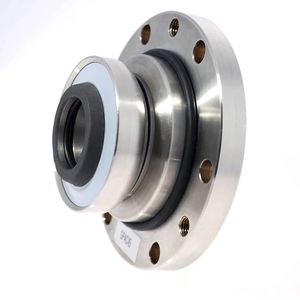

Metal seal O-FLEX™O-ringcircularwall

Add to favorites

Compare this product

Characteristics

- Type

- O-ring

- Configuration

- circular

- Material

- metal

- Application

- wall, military, engine

- Fluid

- gas

- Other characteristics

- high-pressure, high-temperature, spring

- Temperature limit

Min.: -272 °C

(-458 °F)Max.: 800 °C

(1,472 °F)- Pressure limit

3,000 bar

(43,511.3 psi)

Description

O-FLEX™ metal O-rings are designed to provide a sealing option for high-pressure/high-temperature applications that require minimal spring back. The O-FLEX™ metal O-ring is made from high strength metal tubing that is coiled, cut and welded to size. It is available in standard cross-section increments of 1/32”. The O-FLEX™ metal O-ring seating load can be adjusted to the application by varying the cross-section and tubing wall thickness.

O-Flex™ Types:

The basic O-FLEX™ is designed for low to moderate pressure applications as high pressure may collapse the exposed tubing wall.

The Self-Energizing O-FLEX™ is designed for high-pressure applications. Small holes are drilled in the tubing wall exposed to the system pressure. These holes create an energizing effect by allowing the pressure to enter the O-FLEX™. As a result, the pressure inside the seal increases with the system pressure and minimizes the possibility of collapsing the exposed tubing wall.

The Pressure Filled O-FLEX™ is designed for Performance Engine applications that require sealing at elevated pressure and temperature in a high cycling environment. The O-FLEX™ is filled with an inert gas that increases in pressure proportional to increases in system temperature. This results in an energizing effect that partially offsets the loss of material strength in service.

MS O-FLEX™: O-FLEX™ Seals for Military Standards. O-FLEX™ Metal O-Rings are designed to provide a sealing option for high pressure/temperature applications that require minimal spring back. The O-FLEX™ is made from high strength metal tubing that is coiled, cut and welded to size.

Catalogs

SEMICONDUCTOR

5 Pages

*Prices are pre-tax. They exclude delivery charges and customs duties and do not include additional charges for installation or activation options. Prices are indicative only and may vary by country, with changes to the cost of raw materials and exchange rates.